Fanuc

-

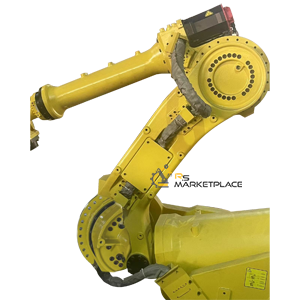

Fanuc R-2000iB 210F

<i class="fas fa-plus"></i>The Fanuc R-2000iB 210F is a floor mounted 6 axis robot. It’s payload of 210 kg and a 2655 mm horizontal reach makes it suitable for many applications including welding, material handling and assembling. The Fanuc R-2000iB has a slim wrist and arm design enabling it to fit into confined spaces. It gives manufacturers greater versatility when dealing with heavy duty workloads. The R-30iA Controller uses advanced technology packaged in a reliable and efficient design. Process capability and open architecture features provide intelligence to improve application and motion performance whilst simplifying system integration. The controller offers controls acceleration and deceleration times. This leads to shorter cycle times. The controller provides an integrated 2D vision system to speed up the installation of vision applications and this can be easily upgraded to a 3D vision system.

Quick View -

FANUC R-2000ib/165F

<i class="fas fa-plus"></i>This category of robot is ideal for spot applications in general.

Quick View -

Fanuc R-2000iB/165R

€21.000,00Fanuc R-2000iB/165R is an intelligent robot with a slim and compact body that packs a punch. Not only does this…<i class="fas fa-plus"></i>Fanuc R-2000iB/165R technical characteristics:

Controlled axes: 6

Repeatability: ± 0.3

Mechanical weight (kg): 1480

● Motion range:

J1 – 370°

J2 – 200°

J3 – 375°

J4 – 720°

J5 – 250°

J6 – 720°

● Maximum speed:

J1 – 115°/s

J2 – 110°/s

J3 – 125°/s

J4 – 225°/s

J5 – 225°/s

J6 – 225°/s

● Fanuc R-2000iB/165R robot footprint – 771 x 610 mm

● Mounting position: floorFanuc R-2000iB/165R key features:

● Rack mounted

For any heavy load project that requires a rack mount, the Fanuc R-2000iB/165R is an ideal choice. This model has precision in motion control and accuracy of repeatability designed for difficult movements, making it the perfect tool for high loads. It features a small arm design with higher torque performance than other models, allowing large components to be fed into the machine with ease. Additionally, its die cast frames and high rigidity designs provide much needed strength and stability when mounting any component or assembly. All of this comes together to create a rack mount system capable of performing any task without fail; it’s a must have for any loading needs.

● Maximum work envelope

With Fanuc’s R-2000iB/165R you can get the best of both worlds, saving valuable floor space while still being granted a massive 3095 mm working area. You don’t have to compromise on your working envelope – Fanuc has got you covered! The robot also offers incredible precision and repeatability, along with heavy payloads and excellent reach capabilities. With this robot, even complex tasks will be completed efficiently and with high accuracy. It provides an ideal robotic arm for manufacturing processes that involve precision movements and lifting heavy objects. Get all the benefits of Fanuc’s maximum work envelope without compromising on the size you need in the workspace.Quick View -

Fanuc R-2000iB/210F

€19.250,00Fanuc R-2000iB/210F model is a powerful and versatile addition to the world of robotic arms. Its impressive payload of 210kg…<i class="fas fa-plus"></i>Fanuc R-2000iB/210F technical characteristics:

Controlled axes: 6

Repeatability: ± 0.05

Mechanical weight (kg): 1090

Motion range:

J1 – 370°

J2 – 136°

J3 – 312°

J4 – 720°

J5 – 250°

J6 – 720°

● Maximum speed:

J1 – 120°/s

J2 – 105°/s

J3 – 110°/s

J4 – 140°/s

J5 – 140°/s

J6 – 220°/s

● Fanuc R-2000iB/210 robot footprint – 771 x 610 mm

● Mounting position: floorFanuc R-2000iB/210 key features:

● Heavy payload

Fanuc’s R-2000iB/210F robotic arm is an incredible tool for those who need to handle truly massive payloads. Its 210 kilogram lifting capacity and wide range of applications make it the perfect choice for difficult projects where brute strength is essential. With this powerful robot, even complicated tasks can be done quickly and with minimal effort. No job is too big for Fanuc’s robotics portfolio!

● Perfect for spot welding

Fanuc R-2000iB/210F robot model is an attractive solution for automotive spot welding. It allows for the remote welding of heavy payloads, a big advantage over traditional manual methods. Its impressive performance and easy availability make it well suited to many industrial applications, while its precision and accuracy offer consistently reliable results. As one of Fanuc’s most popular robots, the Fanuc R-2000iB/210F offers users in the automotive industry an efficient and cost-effective way to accurately weld difficult-to-reach spots or high workloads with ease.Quick View -

Fanuc R2000i/165F RJ3IB mounted on linear track

<i class="fas fa-plus"></i>Fanuc R2000i with RJ3iB controller industrial robot is a 6 axis robot used by automotive companies worldwide. It is among the fastest robot arms in its class. This makes the R2000i very useful in many applications where the ability to fit in confined spaces is important, even the narrow wrist helps in this. The wrist of the R2000i has an IP rating of IP67 and the rest of the arm is IP54. It is mounted on a 4.6 m long linear track, thus providing maximum range. Lower arm is single sided; this allows the robot to ?flip over? and work behind itself. The arm is light, fast and compact so it is without a doubt a very multipurpose robot. The R2000i comes with the Fanuc RJ3iB controller. Benefits of the RJ3iB include fast boot up time, excellent connectivity, powerful programming language, built in safety circuits, expandable I/O and bus options.

Quick View -

-

Fanuc S-500iB , R-J3iB

<i class="fas fa-plus"></i>The FANUC S-500iB robot is engineered for precision, high-speed operation and designed for a variety of manufacturing processes.

Quick View -

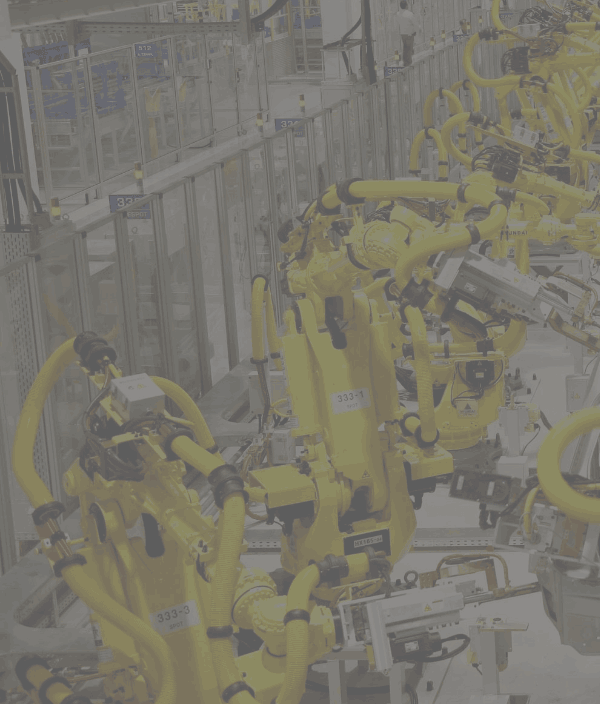

Fanuc Welding Solution

Integration services and robotic welding solutions based on Fanuc robots offer a promising future for businesses looking to improve their…<i class="fas fa-plus"></i>At our company, we prioritize the integration of industrial robots and industrial control systems with a strong focus on quality and honesty. As a system integrator of FANUC industrial robots, we pride ourselves on offering flexible and reliable solutions for a variety of material handling applications such as welding, palletizing, and pick-and-place. We go above and beyond by providing a complete industrial robot integration solution that includes everything from installation and programming to custom grippers, conveyor belts, and more. Our team utilizes cutting-edge technology, such as machine vision and sensors, to ensure that our solutions meet the highest standards of quality. At the core of our business is a commitment to honesty, which means that we prioritize open communication and transparency with our clients every step of the way.

We provide a Fanuc welding solution and full integration.

Quick View -

Full System-Fanuc LR Mate 200iD/4s

€19.500,00<i class="fas fa-plus"></i>The Fanuc LR Mate 200iD/4s is highly compact. The 6 axis short arm robot has been designed for confined spaces and compact machines. This model is easy to integrate.

The robot comes with a R-30iB Plus controller, the new standard for smarter productivity. It is destined to contribute to the easier use of robots and automation in the manufacturing industry. Featuring a new generation of advanced integrated hardware and more than 250 software functions, it is THE key to robot performance in terms of cycle-time, speed, accuracy and safety. It has been designed for increased user friendliness and minimal energy consumption.Quick View -

New Fanuc ArcMate100/7L with control R30iB , Lorch S3 pulse welding /compact cell

<i class="fas fa-plus"></i>This category of robot shows flexibility and capacity to arc welding and cutting applications. The productivity is improved by Fanuc technology with integrated hardwares and software functions.

Quick View