KUKA

-

-

KUKA KR360 L240

The KUKA KR360 L240 is a powerhouse of a robot that is capable of handling heavy duty operations with ease.…<i class="fas fa-plus"></i>The KUKA KR360 L240 is an impressive piece of machinery that can take on heavy duty operations with ease. Built to withstand the most demanding of tasks, this robot has a high loading capacity that makes it suitable for a variety of industrial applications. Its durability and strength make it a reliable option for businesses that require heavy lifting, and its large size ensures that it can handle even the most difficult tasks. With the KUKA KR360 L240, companies can reap the benefits of automation while ensuring that their operations are efficient and reliable.

Quick View -

KUKA KR360 L240 Robot

RSM offers the KUKA KR360 L240 Robot, ideal for heavy-duty industrial operations. 6-axis robot arm with 240 kg payload and…<i class="fas fa-plus"></i>We are proud to present to you the KUKA KR 360 L240 robot.

The KUKA KR360 L240 robot is a versatile 6-axis robot arm that offers a maximum payload of 240 kg and a reach of 3326 mm, making it suitable for various industrial applications. The repeatability of this robot is an impressive 0.08 mm, ensuring precise and accurate movements.

One of the notable features of the KUKA KR360 L240 robot is its adaptability to various tasks. It is commonly used for 3D printing, assembly, dispensing, finishing, material handling, palletizing, pick and place, and remote tcp. This robot’s exceptional capabilities make it a preferred choice for companies that require high-performance robots that can handle multiple tasks.

Moreover, the KUKA KR 360 L240 robot’s robust construction ensures its reliability and durability. It has a robot mass of 2411 kg, making it a heavyweight robot that can withstand harsh industrial environments.

In terms of programming and control, the KUKA KR 360 L240 robot is easy to operate, making it suitable for both novice and experienced operators. The KUKA KR C4 controller powers this robot and allows for quick and straightforward programming.

In conclusion, the KUKA KR 360 L240 robot is a reliable and versatile robot arm that can handle a wide range of industrial applications. Its precision, adaptability, and durability make it an excellent investment for companies looking to improve their production processes.

Quick View -

KUKA KR360 L280

<i class="fas fa-plus"></i>The KR360 is a large and very durable robot. It is suitable for heavy duty operations with its high loading capacity.

Quick View -

KUKA KR360-1

<i class="fas fa-plus"></i>The KR360 is a large and very durable robot. It is suitable for heavy duty operations with its high loading capacity.

Quick View -

KUKA KR360-2

<i class="fas fa-plus"></i>The KR360 is a large and very durable robot. It is suitable for heavy duty operations with its high loading capacity.

Quick View -

KUKA KR360-2 KRC2 Ed05

<i class="fas fa-plus"></i>The KR 360-2 industrial robot for handling heavy loads and is one of KUKA’s most powerful robots. It guarantees a high precision in the repetition and a wide field of work. Compact robot that offers increased production quality. Equipped with KRC2 Ed05 control. Reduce automation costs for integration and maintenance.

Quick View -

KUKA KR5

€12.500,00• Robust design & reliable • Longer service intervals • Increased efficiency • Easy maintenance Ideal for the following applications:…<i class="fas fa-plus"></i>Some key features:

Manipulator:

• Manipulator colour: White

• Protection: Waterproof

• Signs on manipulator: KUKA

• Standard calibration method: Axis Calibration

• Controller variants: Single cabinet

• Underwriters Laboratory: CE

• Mains voltage: 3x220V

• Mains connection type: Cable gland

• Mains switch: Rotary switch

• Door interlock: Door interlock

• Room temperature: Max 45 C

• As IS

Floor cables:

• Manipulator cable – Length: 5m

• Application interface Conn. to: Cabinet

• Connection of Parallel Communication: 5mQuick View -

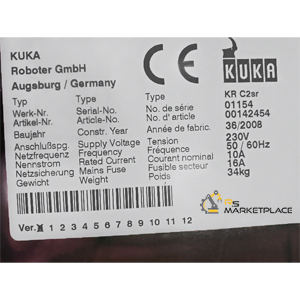

Kuka KR5sixx R850

The KUKA KR 5 sixx R850 is a 6-axis robot arm with a 5 kg payload and 855 mm reach…<i class="fas fa-plus"></i>The KUKA KR5 sixx R850 is a versatile and reliable 6-axis robot arm that offers a payload capacity of 5 kg and an 855 mm reach, making it perfect for low payload material handling applications. This compact robot arm offers a repeatability of 0.03 mm, ensuring precision and accuracy in all its movements.

One of the main benefits of the KUKA KR5 sixx R850 is its compact size and longer reach, which allows it to work in tight spaces and cover a larger work area. Its small work envelope is particularly useful in manufacturing facilities where space is limited. Moreover, the KUKA KR 5 sixx R850 is designed to work in various industrial applications, including arc welding, dispensing, remote tcp, and spot welding.

This KUKA robot is equipped with the KUKA KR C2 ED05 controller, which ensures seamless communication between the robot and other machines in the production line. This controller also allows for the easy programming and monitoring of the robot’s movements, making it user-friendly and efficient.

The KUKA KR5 sixx R850 is a cost-effective solution for manufacturers looking to improve their production line’s efficiency and reduce material handling time. Its lightweight design, at only 29 kg, makes it easy to integrate with other machines in the production line, thus increasing productivity.

Overall, the KUKA KR 5 sixx R850 is a reliable, compact, and versatile robot arm that can handle low payload material handling applications with precision and accuracy. Its long reach and small work envelope make it an ideal choice for manufacturing facilities with limited space. Whether it’s for arc welding, dispensing, remote tcp, or spot welding, this KUKA robot arm is a reliable and cost-effective solution for manufacturers looking to improve their production line’s efficiency.

Quick View -

KUKA KR6

€17.500,00• Robust design & reliable • Longer service intervals • Increased efficiency • Easy maintenance Ideal for the following applications:…<i class="fas fa-plus"></i>Some key features:

Manipulator:

• Manipulator colour: Orange std

• Protection: Standard

• Signs on manipulator: KUKA

• Safety Lamp: Safety Lamp

• Standard calibration method: Axis Calibration

• Controller variants: Single cabinet

• Underwriters Laboratory: CE

• Mains voltage: 3×440,480,575V

• Mains connection type: Cable gland

• Mains switch: Rotary switch

• Door interlock: Door interlock

• Room temperature: Max 45 C

• As IS

Floor cables:

• Manipulator cable – Length: 7m

• Application interface Conn. to: Cabinet

• Connection of Parallel Communication: 7mQuick View -

Kuka KR6

<i class="fas fa-plus"></i>Due to its 6 kg loading capacity, the robot is ideal for low payload projects

Quick View -

Kuka KR6

<i class="fas fa-plus"></i>Due to its 6 kg loading capacity, the robot is ideal for low payload projects

Quick View -

Kuka KR6

<i class="fas fa-plus"></i>Due to its 6 kg loading capacity, the robot is ideal for low payload projects

Quick View -

KUKA KR6 R700 sixx KRC4 – fully refurbished

€12.400,00<i class="fas fa-plus"></i>The KUKA KR 6 R700 robot is suitabel for material handling and removal applications, due to its high speed and precision. The robot is versatile and able to work within a large variety of industries and shop floor layouts.

Quick View -

Kuka KR6 R900 sixx

The KUKA KR 6 R900 sixx robot is a 6-axis robot arm with a 6 kg payload and 901 mm…<i class="fas fa-plus"></i>The KUKA KR6 R900 Sixx robot is a versatile and compact 6-axis robot arm designed to improve productivity and accuracy in various manufacturing applications. With a 6.0 kg payload, 901 mm reach, and a repeatability of 0.03 mm, this robot is an ideal option for handling small parts with high precision.

One of the key advantages of the KR6 R900 Sixx is its compact size, which allows it to be adapted to different work environments while saving valuable space. In addition, the KR 6 R900 Sixx KR C4 sets the safety standard and simplifies the interaction between human and machine, ensuring a safe and reliable option for manufacturers.

The KR R900 Sixx series offers a range of models to cater to different industrial applications, including the KR 6 R900 Sixx C‑WP, KR 6 R900 Sixx HM-SC (hygienic machine-floor mount), KR 6 R900 Sixx C‑CR (cleanroom), and KR 6 R900 Sixx C‑HM-SC (hygienic machine-ceiling mount).

For applications that require a robot to work in harsh environments, the KR 6 R900 Sixx WP is an excellent choice. This robot has additional seals on the interior, an extra resistance surface treatment, and stainless steel covers that replace plastic parts. Additionally, the waterproof version of this KUKA small robot has an IP67 protection rating, ensuring it can withstand water and dust with ease.

Overall, the KR 6 R900 Sixx is a precise and adaptable robot that can improve productivity and efficiency in various industrial applications. With its customizable models, high repeatability, and compact design, this KUKA robot is a cost-effective solution for manufacturing processes that require accuracy and reliability. Whether you need to handle small parts or work in a harsh environment, the KR 6 R900 Sixx is an ideal option for enhancing your manufacturing operations.

Quick View -

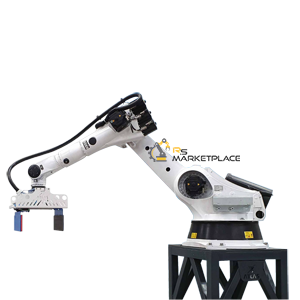

Kuka KR60-3

<i class="fas fa-plus"></i>The Kuka KR60-3 is ideal for general Material Handling. The robot is almost new with less than 100 hours worked

Quick View -

KUKA KR60-3

The KUKA KR 60-3 is a highly versatile industrial robot arm that provides efficient and reliable solutions for a wide…<i class="fas fa-plus"></i>The KUKA KR60-3 robot is a powerful and versatile robotic arm designed to meet various industrial applications. This 6-axis robot arm offers a high payload capacity of 60 kg and an impressive reach of 2033 mm, making it ideal for material handling, palletizing, pick and place, and remote tcp applications. Its high repeatability of 0.06 mm ensures precision and reliability in every task.

This robot arm is designed to save manufacturers money on equipment, thanks to its flexibility to handle several different material handling and removal applications. The KUKA KR60-3 is a cost-effective solution that can perform various tasks with ease.

The KUKA KR 60-3 is available in two variants: the KR60-3 CR, designed for clean-room applications, and the KR 60-3 F, ideal for foundry processes. Both variants feature the KR C4 controller, which provides advanced motion control and programming options.

The KUKA KR 60-3 is easy to program and can be integrated with different software systems and programming languages, making it highly customizable. This robot arm can also be equipped with various end-effectors such as grippers, suction cups, and welding torches to suit different applications.

Overall, the KUKA KR 60-3 robot is a reliable and efficient solution for various industrial applications. Its high payload capacity, long reach, and precision make it suitable for demanding tasks, while its flexibility and versatility make it a cost-effective option for manufacturers. If you’re looking for a robotic arm that can handle multiple applications, the KUKA KR 60-3 should be at the top of your list.

Quick View -

KUKA KR60-L45

KUKA KR 60 L45 is a 6-axis robot arm with 45 kg payload capacity and 2230 mm reach High repeatability…<i class="fas fa-plus"></i>The KUKA KR60 L45 robot is a versatile robotic arm designed to meet the needs of various industrial applications. With six axes of motion, this robot arm can move with precision and flexibility to perform various tasks efficiently.

One of the key features of the KUKA KR 60 L45 robot is its high payload capacity of 45 kg. This means it can handle heavy loads with ease, making it ideal for applications such as material handling, palletizing, and assembly. With its long reach of 2230 mm, the robot arm can access difficult-to-reach areas, making it perfect for tasks such as 3D printing, finishing, and dispensing.

The KUKA KR60 L45 robot is also known for its high repeatability of 0.05 mm. This ensures that the robot arm can perform the same task consistently and with great accuracy, making it ideal for applications that require precision and reliability.

In addition to its robust capabilities, the KUKA KR 60 L45 robot is designed with safety in mind. It features various safety features such as collision detection and protective covers to ensure that it operates safely in a production environment.

The KUKA KR60 L45 robot is also highly customizable. It can be equipped with various end-effectors such as grippers, suction cups, and welding torches to suit different applications. The robot arm can also be integrated with different software systems and programming languages to facilitate programming and control.

Overall, the KUKA KR 60 L45 robot is a reliable and efficient robotic arm with a wide range of industrial applications. Whether you need it for material handling, assembly, palletizing, pick and place, or any other task, this robot arm is sure to meet your needs with its high payload capacity, long reach, and precision.

Quick View -

KUKA KR6sixx R700

The KUKA KR 6 R700 sixx robot is a 6-axis robot arm designed for low payload material handling applications. Key…<i class="fas fa-plus"></i>Introducing the KUKA KR6 R700 sixx robot, a top-of-the-line 6-axis robot arm that offers exceptional performance and versatility. This advanced industrial robot is perfect for low payload material handling applications, thanks to its 6 kg payload and 706.7 mm reach. It provides precise and accurate movements with a repeatability of 0.03 mm, making it a reliable choice for any task.

The KUKA KR 6 R700 sixx robot is highly adaptable, making it suitable for a wide range of applications, such as arc welding, dispensing, remote tcp, and spot welding. As such, it can be utilized in various industries, including automotive, aerospace, and electronics.

Equipped with the KUKA KR C4 controller, this used KUKA robot can use both the compact and small size versions of the KRC4 controller. Additionally, it has an IP54 protection rating, which ensures that it can withstand harsh environments.

The KR 6 R700 sixx robot is designed to optimize dynamic performance with a rated payload of 3 kg. However, it can handle a maximum payload of up to 6 kg, thanks to reduced load center distances and favorable supplementary loads. To verify the specific KUKA Load case, please contact KUKA Service for further consultation.

With a robot mass of 50 kg, the KUKA KR 6 R700 sixx robot is a compact and lightweight machine that can be easily integrated into any production line. It’s an excellent choice for manufacturers who require flexibility and efficiency in their operations.

In summary, the KUKA KR 6 R700 sixx robot is a top-performing robot that offers exceptional speed, accuracy, and flexibility. Its advanced features make it a reliable choice for any low payload material handling application. Contact KUKA Service for further consultation and take advantage of this exceptional robot today.

Quick View -

Kuka KR8 R1620

The KUKA KR8 R1620 robot offers a 6-axis robot arm. It has an impressive 8 kg payload and 1620 mm…<i class="fas fa-plus"></i>The KUKA KR8 R1620 robot is an impressive 6-axis robot arm that offers a 8 kg payload and 1620 mm of reach, making it a valuable addition to a wide range of industrial applications. With a repeatability of 0.04 mm, the KUKA KR 8 R1620 robot provides accurate and consistent results.

One of the strengths of the KUKA KR8 R1620 robot is its versatility. It is commonly used in various applications such as 3d printing, arc welding, dispensing, remote tcp, and spot welding. This flexibility makes it an ideal choice for manufacturing processes that require precision and speed.

The KUKA KR8 R1620 robot’s 6-axis design allows for a wide range of motion, while its 8 kg payload capacity makes it suitable for handling a variety of materials. Its 1620 mm reach also enables it to work on larger products or assemblies.

Additionally, the KUKA KR 8 R1620 robot is designed to provide high accuracy and repeatability, with a repeatability of 0.04 mm. This makes it a reliable and efficient tool for manufacturing processes that require consistent and precise results.

With a weight of 165 kg, the KUKA KR8 R1620 robot is sturdy and robust, yet easy to integrate into existing manufacturing systems. Its flexibility, accuracy, and repeatability make it a valuable asset to any manufacturing process, improving efficiency and productivity.

Investing in the KUKA KR 8 R1620 robot is a wise choice for manufacturers looking to improve their processes and take their production to the next level.

Quick View -

KUKA LBR iiwa 7 R800

KUKA LBR IIWA 7 R800 is a lightweight collaborative robot made of aluminum Features 7 axis of freedom for flexibility…<i class="fas fa-plus"></i>The KUKA LBR IIWA 7 R800 is a cutting-edge collaborative robot that aims to improve precision, flexibility, and safety in manufacturing processes. This innovative robot consists of lightweight aluminum and features 7 axes of freedom, offering unparalleled flexibility and accuracy.

The robot comes equipped with advanced sensors that contribute to its high level of safety and ability to work safely alongside human operators. Unlike other robots, which have sensors only on the end effector, the robot has sensors throughout its body, enabling it to detect movements from all angles.

One of the unique features of the KUKA LBR IIWA 7 R800 is its ease of programming. Users can program this robot effortlessly by simply moving it with their hand, thanks to its intuitive interface and rounded shape that ensure comfortable contact without any sharp edges or pinch points.

Despite its lightweight design, the robot has the ability to handle up to 7 kg of payload, making it an ideal choice for a wide range of manufacturing applications. Moreover, it has a horizontal reach of 800mm and a repeatability of ±0.1mm, ensuring consistent and precise results every time.

The KUKA LBR IIWA 7 R800 is an articulated robot that can be mounted on the floor, inverted, or angled, providing maximum flexibility for different manufacturing environments. With its advanced sensors, intuitive programming interface, and lightweight design, this robot is a game-changer in collaborative manufacturing, providing increased efficiency, productivity, and safety for manufacturers. Therefore, investing in the this robot can take your manufacturing processes to the next level.

Quick View -

Kuka LBR5

€28.000,00• Lightweight • Able to detect contours quickly under force control • Specialized in delicate assembly work<i class="fas fa-plus"></i>The LBR can detect contact immediately and reduces its level of force and speed instantly. Its position and compliance control enables it to handle delicate components without creating crushing and shearing hazards.

Quick View -

KUKA Linear Unit KL 250-3

<i class="fas fa-plus"></i>KUKA linear units are translational motion units Linear units can be used to extend a robot?s work envelope or alternatively to move workpieces or tools within the work envelopes of a number of robots. This allows applications such as the tending of more than one machine or fixture, order picking from rows of pallets, or work on very large components. Control of the linear unit is integrated as a mathematically coupled axis in the robot controller, dispensing with the need for an additional controller.

Quick View -

Kuka Robot KR 200

Kuka Robot KR 200 welding is an innovative technology that makes welding work easier and faster. This robot uses advanced…<i class="fas fa-plus"></i>The Kuka Robot KR 200 has become a reliable tool for industries that require a robot with a good reach and load capacity. Its durability is well-known among its users, proving to be a long-lasting investment. Plus, its versatility makes it suitable for various operations, such as assembly and loading tasks. With the ability to work in any environment and handling different materials, the KR 200 has become a trusted robot in many factories. Companies that have implemented this robot have seen many benefits in terms of productivity, efficiency, and cost-effectiveness. Overall, the Kuka Robot KR 200 is a worth it investment for businesses that require a useful and flexible robotic arm.

Quick View -

Palletizing solution for bags

This new palletizing solution for bags is the ultimate combination of robotics and engineering. Designed with a robot arm specially…<i class="fas fa-plus"></i>Palletizing solution for bags main elements:

● Kuka KR210

The KUKA KR210 6-axis industrial anthropomorphic robot we are utilizing is specially equipped with a high-powered KRC2 controller, ensuring optimal performance. With this system, we can handle products with incredible speed and accuracy; even more so than traditional manual bags palletizers. All the necessary sensors and physical stops provide the robot with exact product location coordinates. This allows us to automate these processes quickly and precisely in line with the quickening pace of industry workflow demands.

● Clamp tool

The innovative clamp tool is a specialized box palletizer designed and configured to capture and deliver boxes with ease. This machine works by using a system of compression blades that removes the bags from a capture table. These features provide better control over the process ensuring accuracy and reliability for every job that requires material handling. Furthermore, the tools are safe and user-friendly, so any operator can understand how to use them quickly and efficiently. The clamp tool certainly makes the process of moving heavy bags much faster and easier than other manual methods used in logistics and transportation.

● Modular belt conveyor

A palletizing solution for bags, using a specially configured motorized modular transport belt, provides the ultimate precision in product handling. Equipped with the necessary stops and defenses to enable optimal gripping, as well as sensors and physical stops to provide the robot with information on positioning of the product, this machinery offers an efficient automated means to move materials quickly and accurately. With its low risk factor and increased safety by computer and technology integration when it comes to manipulating objects, this type of machinery is sure to play a growing role in industrial steps around the globe.Quick View -

Palletizing solution for boxes

A robotic cell for palletizing boxes is a great solution for streamlining the process of packing and loading pallets with…<i class="fas fa-plus"></i>Palletizing solution for boxes main elements:

● Kuka KR210

The KUKA KR210 6-axis industrial anthropomorphic robot we are utilizing is specially equipped with a high-powered KRC2 controller, ensuring optimal performance. With this system, we can handle products with incredible speed and accuracy; even more so than traditional manual box palletizers. All the necessary sensors and physical stops provide the robot with exact product location coordinates. This allows us to automate these processes quickly and precisely in line with the quickening pace of industry workflow demands.

● Clamp tool

The innovative clamp tool is a specialized box palletizer designed and configured to capture and deliver boxes with ease. This machine works by using a system of compression blades that removes the boxes from a capture table. These features provide better control over the process ensuring accuracy and reliability for every job that requires material handling. Furthermore, the tools are safe and user-friendly, so any operator can understand how to use them quickly and efficiently. The clamp tool certainly makes the process of moving heavy boxes much faster and easier than other manual methods used in logistics and transportation.

● Modular belt conveyor

A palletizing solution for boxes, using a specially configured motorized modular transport belt, provides the ultimate precision in product handling. Equipped with the necessary stops and defenses to enable optimal gripping, as well as sensors and physical stops to provide the robot with information on positioning of the product, this machinery offers an efficient automated means to move materials quickly and accurately. With its low risk factor and increased safety by computer and technology integration when it comes to manipulating objects, this type of machinery is sure to play a growing role in industrial steps around the globe.Quick View -

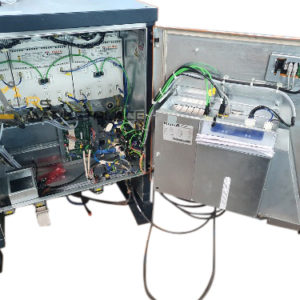

Production lines + Full Systems

<i class="fas fa-plus"></i>The company designs and produces production lines and production stations for several applications such as pick and place, palletizing,

packaging, gluing etc..

They are specialized in robotic stations with conveyors. In order to make the procedure more efficient, the company created a 3D vision system, to make the task easier. The robot knows its position while scanning.

With the 3D vision system implemented by the company, cameras and sensors are not required anymore.

The system is controlled by a controller. The kit is installed on the robot. The kit is scanning, it becomes the

eyes of the robot, and the information is sent, so that the robot knows and can measure the length and the task

to be done.Quick View -

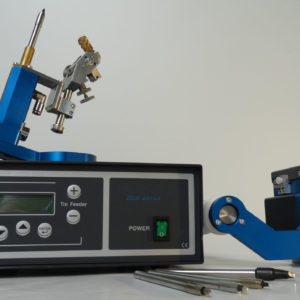

Robotic Soldering Solution

€9.000,00This solder controller is very effective and easy to maintain. It is a stand-alone solution, that can be bought individually.<i class="fas fa-plus"></i>This solder controller is very effective and easy to maintain. It is a stand-alone solution, that can be bought individually.

Quick connection and easy programming makes the product user-friendly. Robotic soldering is also a significant energy saving. Built-in standby menu allows you to lower the temperature so that you do not needlessly heat the soldering tip while waiting. Retooling soldering head is only a tip replacement, so it’s very easy.

The solder controller is great for lead soldering and lead-free soldering. The built-in tip cleaning system is an additional advantage. Additional options include a calibration system and a temperature measurement with a pyrometer. The company ensures high process repeatability and excellent temperature control.Quick View