Find Your Accessories Here

Products

-

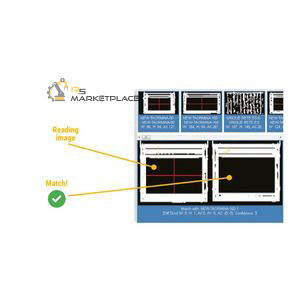

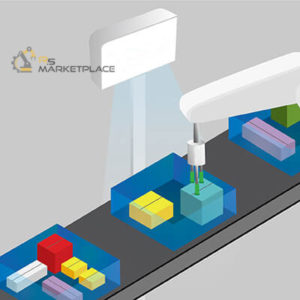

2D system for painting application

€42.200,00• It creates the painting path independently • It associates the painting path with a recipe that can be set…<i class="fas fa-plus"></i>Quick ViewThe product is a system composed of a dedicated software and a pair of photoelectric barriers. It is used on a line, and can identify 2D surfaces.

It creates the painting path independently and associates it with a recipe that can be set by an operator. The recipe is based on a series of spraying parameter.

During an initial work phase, recipes are created for each piece, once that’s completed, the only thing left to do is to load the conveyor with the pieces needing to be painted.

The 2D system recognizes the parts, associating them with the corresponding recipe and creates the best painting path. -

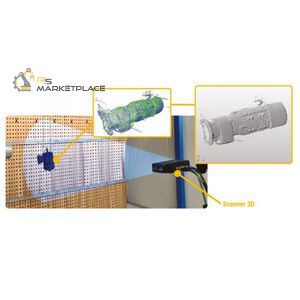

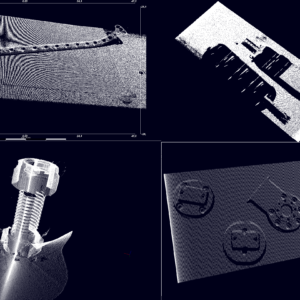

3D Applications Customized Tool

3D Vision System • Can be used for the following robot applications: Pick & Place, Sorting, 3D Applications, Object Identification,…<i class="fas fa-plus"></i>Quick View3D applications customized system is a tool intended for:

• Integrators

• Machine builders

• Industrial end-users

This is an ideal tool for any robotic professional that is willing to develop its own 3D vision applications.

Some key features:

Pixels resolution: From 2.3 M to 5 M depending the option

Camera Resolution: From 1920 x 1200 to 2590 x 2048 depending the option

Working extent : From 450 to 2000 mm approx.

Scanning Time: From a minimum of 0.3 Sec to a minimum of 0.8 Sec. -

3D system for painting application

€47.850,00• Recognizes the inclination and position of the pieces • Automatically adjusts the painting path. • High standard quality services…<i class="fas fa-plus"></i>Quick ViewThe 3D Image system is a system consisting of management software and one or more 3D scanners mounted on a line capable of recognizing the size of three-dimensional objects and associating the corresponding painting program.

In a first phase of work the programs for each type of piece are created, after which it is simply necessary to load the supply line with the pieces to be painted.

The 3D image system pro will take care of recognizing the pieces through its 3D scanners and applying the relative painting program.

It recognizes the inclination and position of the pieces and automatically adjusts the painting path.

It can distinguish between objects of different thickness.

It recognizes the real position and adjusts the painting path. -

3D Vision Creation

Software for the following applications: • Testing & Measuring • Pick & Place • Material Handling • Palletizing • Object…<i class="fas fa-plus"></i>Quick ViewThe software has the ability to transform any camera into a 3D measurement device.

It has the capacity to detect objects and extracts their position and orientation from a single image.

6 numbers are provided for any selected object

• Position X,Y,Z

• Orientation angles A,B,C

Numerous advantages:

• Recognize objects for robots without coding

• Any kind of cameras can be used (webcam, smartphone etc…)

• Uses low cost sensor

• No additional equipment needed

Other advantages:

• Speed:

• No point clouds

• Using NVIDIA GPU can run 30 frame/sec

• Fast object tracking

Flexibility:

• Define objects for robots without coding

• Any camera : WebCam, Industrial even Smartphone

• Working range could be easily adapted

• System setup

Precision:

• RGB camera allows to use different optics

• Getting close to the object allows submillimeter position accuracy

Price:

• Uses low cost sensors

• Can run on a computer with GPU or NVIDIA JATSON

• No additional equipment

• Competitive software pricing -

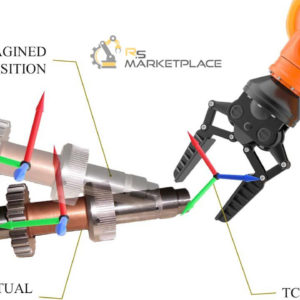

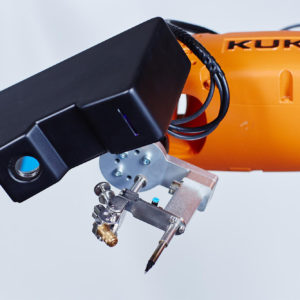

3D Vision Guided Robot

3D Vision System • Suitable to more than 20 world known robots and PLC brands • Can be used for…<i class="fas fa-plus"></i>Quick View3D vision guided robot tool benefits:

• Analyzes and identifies randomed items,

• Pinpoints their positions and orientations

• Gives a command to the robot to fulfill a precise task following an automatically generated path.

• With a minimum scanning time of 0.3s, the system reduces the need for fixtures and precise positioning in the manufacturing process

• Can quickly identify the products features and changes.

3D vision guided robot (VGR) can be used for applications including:

Sealing, welding and polishing among others.

The solution is compatible with most of the industrial robots such as:

Kuka, Yaskawa, ABB, Omron etc… including Collaborative robots. -

3D Vision System

The 3D vision system is a technology with numerous benefits for robotic applications. Its capabilities are extensive, including material handling,…<i class="fas fa-plus"></i>Quick ViewThe 3D vision system offers a multitude of benefits that make it an ideal product for handling a large variety of items stored in warehouses. One of its unique features is the ability to control grippers, ensuring careful picking up of objects. In addition, the system can quickly scan the dimensions of a box, which enables it to identify the best location for an item. The product also has a simple user interface, which makes it easy for users to build several packaging applications without any code writing. What’s more, the solution is compatible with most industrial robots and cobots, including collaborative robots, which makes it an ideal choice for many companies looking to streamline their warehouse processes.

-

3D Vision System Pick & Place Application

• Suitable for more than 20 robots brands • Can be used for the following robot applications: Pick & Place,…<i class="fas fa-plus"></i>Quick View3D Vision System Pick & Place application benefits:

• The solution is compatible with most of the industrial robots such as Kuka, Yaskawa, ABB, Omron etc… including collaborative robots.

• The product is an AI powered tool that can pick random or unknown objects despite the appearance, spatial location or orientation by using 3D machine vision to generate high quality point clouds.

The 3D vision system contains three distinct but seamlessly integrated hardware and software modules:

• 3D scanner, Image analysis software and Bin collision Avoidance.

• The system is ideal for:

Kitting which means picking different items located in different places, and placing them in a kit.

• Highly recommended for complex patterns

• The 3D vision can recognize and pick individual product from a pile of thin material such as metal, paper, rubber etc.. -

3D-Vision System

€20.000,00This 3D Vision System is an eye for the robot. The advanced optical system, positioning and scanning algorithms allow for…<i class="fas fa-plus"></i>Quick ViewThis 3D Vision System is an eye for the robot. The advanced optical system, positioning and scanning algorithms allow for the offset of production processes and visual inspection of items. The robot arm with vision system scans the workspace and finds the items that are needed according to the models, and can also perform other activities on it – packing, pick & place, soldering, assembly.

-

a cutting-edge solution 3D printed grippers

✓ Gripper specially developed using the 3D printing process<i class="fas fa-plus"></i>Quick ViewThese grippers are specially developed using the 3D printing process.

They have internal vacuum generation capabilities and can be customized to suit specific needs.Customizable design: The grippers can be 3D printed to fit a wide range of objects

and are customizable to meet the specific requirements of your application.Lightweight: The grippers are 3D printed using high-strength, lightweight materials,

making them easy to manipulate and reducing the load on the robotic arm.Durable: The grippers are designed to withstand the rigors of industrial environments

and provide long-lasting performance.Cost-effective: 3D printing technology allows for faster production and lower costs

compared to traditional manufacturing methods.With their advanced design and 3D printing technology, the grippers offer a cost-effective

and customizable solution for robotic grasping and manipulation. -

A revolutionary solution – Multiple-removal gripper

✓ Adaptation of existing gripping systems ✓ Safe component removal ✓ Precise removal process<i class="fas fa-plus"></i>Quick ViewMultiple-removal gripper is a revolutionary solution for efficient and precise part removal in industrial automation applications.

This gripper is designed to be lightweight, durable and customizable,

making it ideal for a wide range of applications.This gripper is designed to remove 32 razor blade covers at once.

It uses tubular gripper profiles and has the advantage of several suction pads that can

be connected to one vacuum source.Multiple-part removal: The gripper is designed to remove multiple parts at once,

making it ideal for high-volume production lines.Customizable design: The AGS Multiple-removal gripper can be customized to fit a wide range of objects

and is built to meet the specific requirements of your application.Lightweight: The gripper is 3D printed using high-strength, lightweight materials,

making it easy to manipulate and reducing the load on the robotic arm.Durable: The gripper is designed to withstand the rigors of industrial environments

and provide long-lasting performance. -

AIR10-1420

€13.339,00This robot is known for its: • High speed • High precision and high stability • Strength Can be used…<i class="fas fa-plus"></i>Quick ViewKey features:

Weight: 160 Kg

Repeatability: ±0.02mm

Working range:

Axis 1 rotation: -170°/+170°

Axis 2 arm: -85°/+150°

Axis 3 arm: -95°/+170°

Axis 4 wrist: -195°/+195°

Axis 5 bend: -135°/+135°

Axis 6 turn: -360°/+360° -

AIR7-920

€12.479,00This robot is known for its: • High speed • High precision • Bigger payload & longer robot reach. •…<i class="fas fa-plus"></i>Quick ViewKey features:

Weight: 53 Kg

Repeatability: ±0.02mm

Working range:

Axis 1 rotation: -170°/+170°

Axis 2 arm: -100°/+135°

Axis 3 arm: -120°/+156°

Axis 4 wrist: -200°/+200°

Axis 5 bend: -135°/+135°

Axis 6 turn: -360°/+360°

Special Selection

Inspired by you

Your Selection from Our RS Marketplace

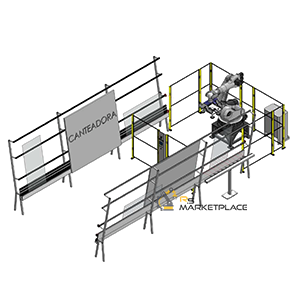

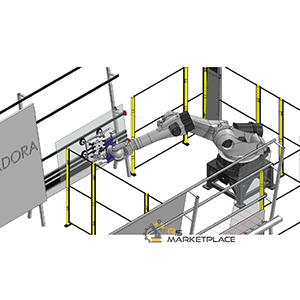

Handling solution for boards

Handling solution for boards key features:

● Works with any type of material

If you’re in need of an efficient and reliable handling solution for boards of any kinds, look no further! Whether it’s wood, granite, countertops or glass – it doesn’t matter; our product is guaranteed to work with any material. With its unique design, our product ensures that all jobs are accomplished in a safe and secure manner. Thanks to our easy-to-use system, you now have the peace of mind that your goods and materials will be handled appropriately. Get exactly the support you need for your specific projects!

● Robust and easy to use

A handling solution for boards that requires virtually no technical expertise is now available via the user-friendly HMI screen. It’s an extremely robust and easy-to-manage installation process. Thanks to this new technology, it’s possible to implement the board handling solution without having prior knowledge of the systems involved. The intuitive nature of the user interface makes it possible to complete the installation quickly and accurately, setting a new standard for efficient implementation.

Pallets manufacturing solution

Pallets manufacturing solution key features:

● Nailing of a panel every 30 seconds

Manufacturers can save significant time, effort and cost when it comes to pallet production through the use of an automated solution. This is a great solution for expediting the process of nailing a pallet every 30 seconds. By using such an automated nailing system, the pallet is accurately formed and nailed in one continuous operation, thus dramatically reducing labor costs. The quality of each pallet is also improved significantly as compared to manual production systems without issue of inconsistency or misalignment. Thanks to this pallets manufacturing solution, companies can now create more product with less time and resources.

● The ideal pallets manufacturing solution for your core production is here. This system is ready to meet any type of pallet requirement, regardless of custom formats. Easy to install and use, it offers a reliable solution tailored to your specific needs and processes. With the latest technology, you can trust it will optimize every aspect of your production line. Get the perfect pallet-building solution today.

Handling solution for glass sheets

Handling solution for glass sheets main elements:

● Kuka KR210

The KUKA KR210 6-axis industrial anthropomorphic robot we are utilizing is specially equipped with a high-powered KRC2 controller, ensuring optimal performance. With this system, we can handle products with incredible speed and accuracy. All the necessary sensors and physical stops provide the robot with exact product location coordinates. This allows to automate these processes quickly and precisely in line with the quickening pace of industry workflow demands.

● Clamp tool

The innovative clamp tool is designed and configured to capture and deliver the glass sheets with ease. This machine works by using a system of compression blades that removes the bags from a capture table. These features provide better control over the process ensuring accuracy and reliability for every job that requires material handling. Furthermore, the tools are safe and user-friendly, so any operator can understand how to use them quickly and efficiently. The clamp tool certainly makes the process of moving heavy bags much faster and easier than other manual methods used in logistics and transportation.

● Modular belt conveyor

A handling solution for glass sheets provides the ultimate precision in product handling. Equipped with the necessary stops and defenses to enable optimal gripping, as well as sensors and physical stops to provide the robot with information on positioning of the product, this machinery offers an efficient automated means to move materials quickly and accurately. With its low risk factor and increased safety by computer and technology integration when it comes to manipulating objects, this type of machinery is sure to play a growing role in industrial steps around the globe.

Mobile Robots

The company implements mobile robots to support the work of the warehouse, transfer of loading to production lines or in the production line. Possibility to manage a fleet of robots.

Material Handling Robotic Solution

Material handling robotic solution in industrial settings has often been a time-consuming and arduous task. Fortunately, the Kuka industrial robot is changing the game for good. With its precision, speed, and adaptability, this automated solution is revolutionizing material handling in numerous industries. It can maneuver bulky parts, organize crates, and load and unload items with ease. This robot not only increases productivity by shortening cycle times but also enhances workplace safety by performing hazardous tasks that human personnel would otherwise have to execute. The Kuka robot sets a new standard for efficient and streamlined material handling.