Robotic Arms

a valuable tool in various industries

What are Robotic Arms

A mechanical arm is designed to perform tasks that would typically be performed by a human arm.

It consists of several joints or segments, which are connected by electric motors, gears, and sensors. These joints allow the arm to move in various directions and perform precise movements.

How it can help your business

Manufacturing:

Robotic arms can be used in manufacturing plants to perform tasks such as welding, assembly, and material handling. They can operate continuously without getting tired or making mistakes, leading to increased productivity and efficiency.

Packaging:

Robotic arms can be used to pick and place products in packaging containers, reducing the need for human labor and increasing the speed and accuracy of the process.

Inspection:

Robotic arms can be equipped with sensors and cameras to inspect products for defects, ensuring high-quality control and reducing the need for human labor.

Healthcare:

Robotic arms can be used in healthcare for surgical procedures, rehabilitation, and assistance for people with disabilities.

Robotic arms can help a business by increasing efficiency, productivity, and quality control. They can also reduce the need for human labor, which can save time and money in the long run. Additionally, robotic arms can be programmed to perform tasks that are difficult or dangerous for humans, improving safety in the workplace.

Types of

robotic arms

Cartesian or Gantry Robot:

This type of robot has three linear axes that move in X, Y, and Z directions, and it is often used for pick and place applications in manufacturing.

Articulated Robot:

This type of robot has rotary joints that can move in multiple axes, providing greater flexibility in movement. They are often used in manufacturing, painting, and welding applications.

Collaborative Robot (Cobot):

This type of robot is designed to work safely alongside humans, without the need for protective barriers. They are often used in manufacturing, healthcare, and logistics applications.

SCARA Robot:

SCARA stands for Selective Compliance Assembly Robot Arm. This type of robot has a combination of rotary and linear motion axes and is designed for high-speed, precision assembly tasks.

Cartesian:

Cartesian robots are a powerful and accurate type of robot that is incredibly versatile.

They make up the framework for motion, with three linear actuators moving left/right in the x-axis plane, then upwards/downwards on the y-axis plane, and finally back & forth along its z-axis; allowing them to be used efficiently within many production settings across various industries. These robots’ rigid design also makes them ideal for intricate tasks requiring fine positioning control – from 3D printing to laser cutting!

Cylindrical:

Cylindrical robot arms are an efficient and innovative solution for small-scale automation. With a single vertical member that rotates the arm horizontally, these robots can stretch and contract to accomplish simple yet precise jobs in tight spaces. Their compact form factor makes them well-suited for projects with limited space requirements.

Spherical/Polar:

The first industrial robot was a revolutionary spherical model – a simple design unlike anything seen before. Its distinguishing feature is the addition of an extra rotary axis, giving it unique capabilities like the ability to rotate vertically for low-speed and uncomplicated tasks that wouldn’t be feasible with cylindrical designs.

Parallel/Delta:

The invention of the industrial robot marked a new era in manufacturing – introducing an innovative, novel spherical model with remarkable rotational capabilities. This game-changing design allowed for simpler tasks to be completed faster and more efficiently than ever before – providing industry professionals with entirely unprecedented abilities that have since been utilised all over the world.

Anthropomorphic:

Anthropomorphic robots are quickly becoming a common sight in industrial settings as technology advances. With two or more arms and a friendly face, these lifelike machines can easily be mistaken for their human counterparts, even working alongside them on the job. As robotics grows increasingly sophisticated in its ability to collaborate with humans safely and efficiently, expect to see further integration of anthropomorphized robots into our daily lives!

Applications

Manufacturing:

Robotic arms are commonly used in manufacturing for tasks such as welding, painting, assembly,

and material handling.

Packaging and logistics:

Robotic arms can be used for pick and place operations in packaging and logistics applications, reducing the need for human labor and increasing the speed and accuracy of the process.

Agriculture:

Robotic arms are used in agriculture to plant, harvest, and maintain crops, reducing the need for human labor and increasing efficiency.

Healthcare:

Robotic arms are used in healthcare for surgical procedures, rehabilitation, and assistance for people with disabilities.

Space exploration:

Robotic arms are used in space exploration for tasks such as assembling and repairing spacecraft.

Entertainment:

Robotic arms can be used in entertainment for special effects and animatronics.

Education and research:

Robotic arms are used in educational and research settings to teach students and researchers about robotics and to conduct experiments.

Palletizing:

Automating the process of palletizing with robotic arms can be an efficient, cost-effective solution for businesses. By freeing up human workers from performing manufacturing tasks that can potentially lead to injuries, these robots help create a safer environment while ensuring products are accurately placed on pallets every time.

Material handling:

Robotic material-handling arms are revolutionizing warehouses, with their ability to securely store, locate and transfer materials safely. Not only do they increase delivery speed for customers but also safeguard personnel working in a facility from workplace accidents – all while ensuring maximum efficiency is maintained!

Welding:

Welding is a key element in the production of many products, from cars to medical devices. To ensure accuracy and quality when performing this required task, manufacturers are increasingly turning to robotics with advanced vision systems and AI capabilities for inline inspection. This brings welding one step closer to full automation – revolutionizing manufacturing processes everywhere!

Inspection:

By introducing robots equipped with innovative vision and AI solutions, businesses can be proactive in ensuring quality production. These advances enable the early detection of any potential issues, resulting in reduced waste and downtime while improving overall efficiency.

Pick & Place:

Pick-and-place robots are revolutionizing the world of manufacturing and logistics. Their advanced machine vision technology can quickly identify, grasp, and transport objects with unparalleled speed – enabling goods to reach their destination faster than ever before! This groundbreaking innovation is not only increasing production efficiency but also making sure that products arrive in record time.

The Benefits of Industrial Robotic Arms

Robot arms provide numerous advantages to businesses, such as improved safety and efficiency. These mechanical marvels can tirelessly work 24/7 without fatiguing while keeping hazardous or risky tasks away from humans – quite a boon for productivity! Even more impressive is the precision they offer; automated robotic arms are far better at executing highly delicate activities requiring extreme accuracy than any human could. And when your business priorities change, no need to worry – these amazing machines have immense flexibility and their use is only limited by our imaginations – robot arms can be remounted onto different platforms like AMRs, stationary assembly lines, etc.

Famous robotic arms

In space, the Canadarm and its successor Canadarm2 have been used to accomplish astonishing feats like inspecting Space Shuttles with cameras or retrieving satellites from their cargo bay. Even further afield on Mars, robotic arms enable groundbreaking scientific exploration: for example, NASA’s Perseverance rover includes an advanced sample caching arm that can harvest specimens from far away asteroids. TAGSAM is another remarkable robotic arm designed specifically for this purpose – it was mounted aboard OSIRIS-REx spacecraft so as to collect samples off of small asteroids!

The InSight Mars lander’s robotic arm, aptly named the IDA has a remarkable toolkit; boasting an impressive array of camera equipment and grapplers to effortlessly move its special instruments.

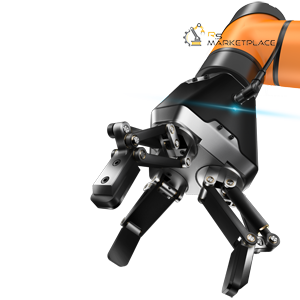

Robotic Hands

Robotic hands, also known as end effectors, can be designed to complete any task. Automotive assembly lines use robot arms for welding and parts rotation so that the car is assembled with precision and accuracy. Additionally, robotic limbs have been developed to imitate human hand movements in order to safely disarm bombs without putting humans at risk of harm.

Our Products

Robotic Arm – ABB IRB2600-12

This robot is a compact and versatile 6-axis industrial robot with a payload capacity of 12 kilograms and a reach of 1.85 meters.

Electric Adaptive Gripper

This gripper is an efficient and versatile tool for automating repetitive tasks and processes in a variety of industries, from auto parts to new energy.

Painting Robot

High-standard quality services. Painting applications for metal and plastic components

Folding Boxes Cobot Solution

This service is ideal for automating the preparation task, and opening and placing boxes in an industrial environment.