RSM MARKETPLACE presents

Your Individual Gripper

The modular design system for flexible gripping

2-Finger

Parallel Cobot Gripper

Mass: 110g

Feed Size: 5 mm – 120 mm

Closing Time: 60 ms

Opening Time: 50 ms speed

Weight: 300g

Typical Gripping Objects: Rectangular or cubic

Typical Gripping Tasks: Chocolates, appetizers, chewing gum, screws, batteries

3-Finger

Centric Cobot Gripper

Mass: 190g

Feed Size: 5 mm – 120 mm

Closing Time: 60 ms

Opening Time: 50 ms speed

Weight: 450g

Typical Gripping Objects: Circular or cylindrical shape.

Typical Gripping Tasks: Picking strawberries, handling fruits, apples, tangerines, figs, eggs and vials.

4-Finger

Centric Cobot Gripper

Mass: 200g

Feed Size: 5 mm – 120 mm

Closing Time: 60 ms

Opening Time: 50 ms speed

Weight: 450g

Typical Gripping Objects: Rectangular or cubic

Typical Gripping Tasks: Picking strawberries, handling fruits, apples, tangerines, figs, eggs

and vial

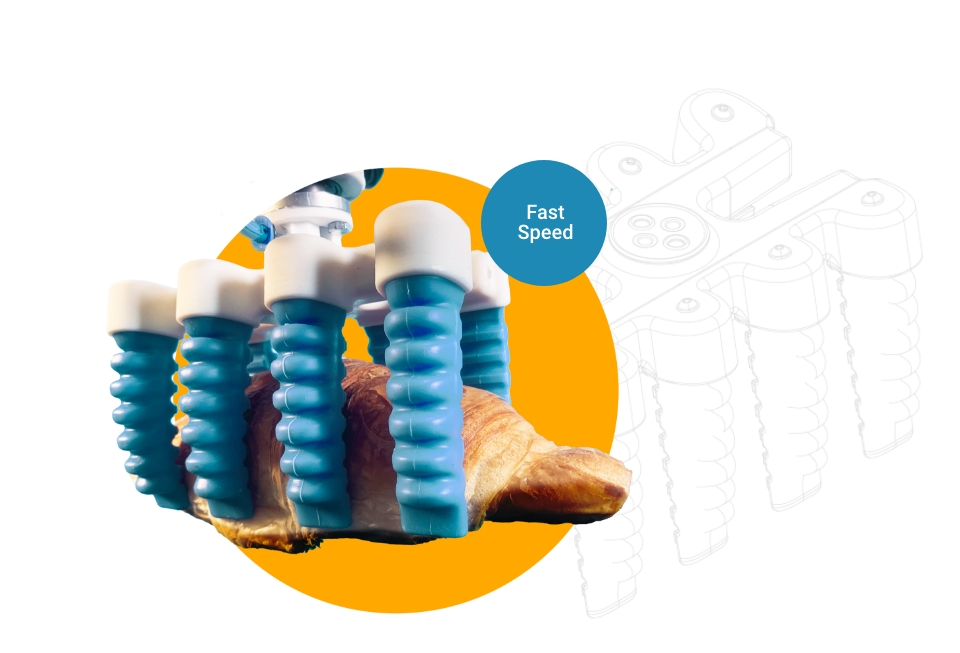

6-Finger

Parallel Cobot Gripper

Mass: 250g

Feed Size: 40 mm – 120 mm

Closing Time: 60 ms

Opening Time: 50 ms speed

Weight: 1200g

Typical Gripping Objects: Rectangular or cubic

Typical Gripping Tasks: Croissants, breadsticks, aluminum foil roll, packaging material,

chicken legs

8-Finger

Parallel Cobot Gripper

Mass: 460g

Feed Size: 40 mm – 120 mm

Closing Time: 60 ms

Opening Time: 50 ms speed

Weight: 1200g

Typical Gripping Objects: Rectangular or cubic

Typical Gripping Tasks: Cucumbers, radishes, baguettes, steaks and bottles

BENEFITS

These are the reasons why we offer the highest reliability in the market!

FDA approved finger material with FDA approved base material for special applications.

A new standard component in produce

handling automation.

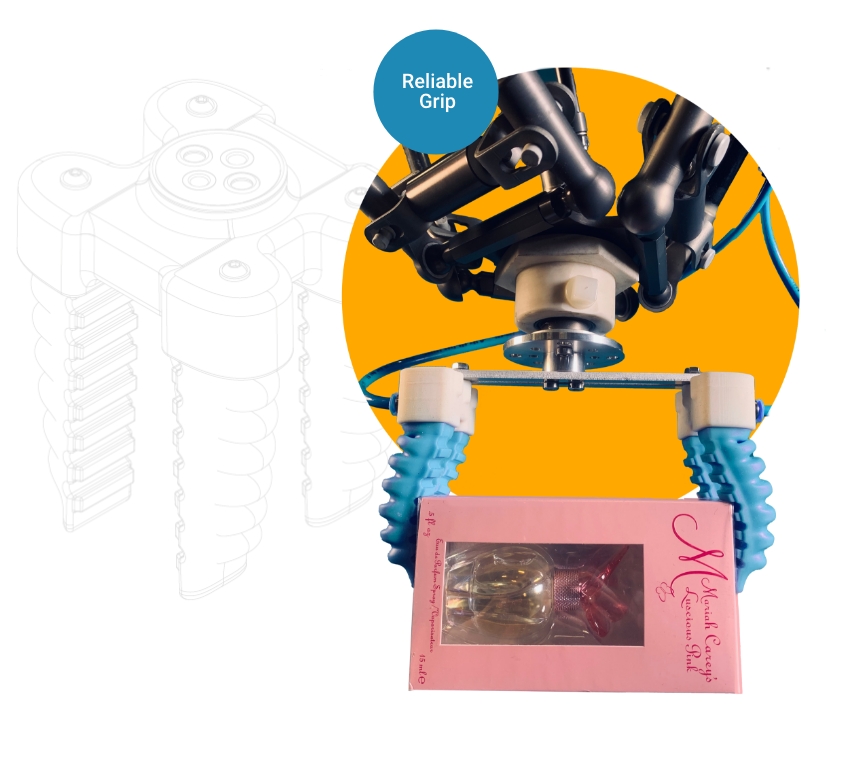

The elasticity ensures a safe and careful gripping of very different shaped products.

Our hygienic grippers are fully washable and meet all food safety regulations.

Soft surfaces are ideal for universal gripping without the need of complex feedback systems.

Our soft grippers are very light integrated and ensure a safe and easy collaboration with humans.

We provide customized gripper configurations to meet all your requirements for a handling application.

With special design features a quick, efficient manufacturing process, you will receive your fully customized gripper within 2 weeks.

Full speed ahead for automation! Using our grippers, more than 60 picks per minute are in reach, even for sensitive products.

We provide what you need!

Pick the gripper

Food Industry Grippers

Bakery goods gripper

Breads, buns, dough. Whether frozen or fresh from the oven.

They all need to be handled with care.

What human hands have been doing for ages is now

within reach for robotic automation.

Thanks to the soft grip and hygienic surface,

all bakery products can be handled with the utmost care.

Universal Gripper

Plastics and Packaging

A perfect gripper for plastics must be soft and conform to the surface without leaving handling marks. Plastics are everywhere. From current containers to food packaging. Where conventional grippers struggle to find a good grip, our softgrippers shine.

Think packaged candy, packed croissants or thin-walled plastic bottles that yield to force.

Control Box

Pneumatics are key to operate a Gripper.

The Kit includes all elements to assemble

4 different grippers.

We guarantee a lifetime of more than 10 million cycles at 1 bar pressure. Hygienic designed.

Easy to use and essentially made for cobots.

WE WORK WITH

Integrators and manufacturers share our passion for automation.

Fish processing machines

High-speed Automation in bakeries

Cobot Automation in bakeries

Plastics

Frequently Asked Questions

SoftGrippers work with compressed air. Applying pressure leads to closing of the fingers. Vacuum opens them.

Our fingers can achieve up to 50 ms for closing and opening speeds. Combined with a delta or scara robot, 60-80 picks a minute is a common operating range.

Our fingers can achieve up to 50 ms for closing and opening speeds. The pressure range is 0.5 to 1.2 depending on the object. Small and fragile ones, like strawberries, are best to be handled at lower pressures, while heavier ones

(a pineapple for example) require a little bit more pressure.

We are guaranteeing for up to 10 million cycles before replacement fingers are needed. What are 10 million cycles? – Calculating with one pick a second, you end up at 3,5 months with 24/7 high speed setups.

We are guaranteeing for up to 10 million cycles before replacement fingers are needed. The fingers are made from FDA certified materials and meet all other food safety regulation criterias. The bases are not in contact with the foods but still, a hygienic design is key for fast and reliable cleaning processes. Ask for a FDA approved surface finnish if you are working with meat, fish and other produce that require an extra hygienic concept.

@ All Right Reserved, RS Marketplace 2022