-

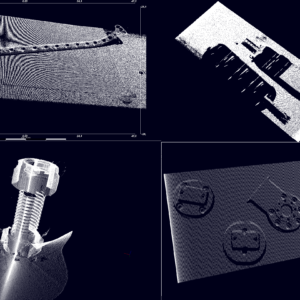

3D-Vision System

€20.000,00This 3D Vision System is an eye for the robot. The advanced optical system, positioning and scanning algorithms allow for…<i class="fas fa-plus"></i>This 3D Vision System is an eye for the robot. The advanced optical system, positioning and scanning algorithms allow for the offset of production processes and visual inspection of items. The robot arm with vision system scans the workspace and finds the items that are needed according to the models, and can also perform other activities on it – packing, pick & place, soldering, assembly.

Quick View -

Consulting – existing production lines

Our experts offer consulting to improve existing production lines.<i class="fas fa-plus"></i>The company provides consulting in pre existing production line, e.g. modernizing. We specialize in KUKA, Mitsubishi, Omron.

Quick View -

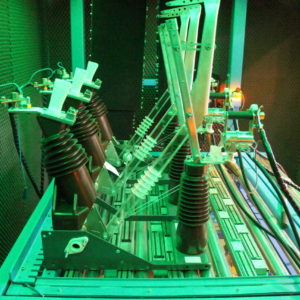

EOL testers

Leak testing, in-line electrical testing or EOL test -

Full Systems for various applications

The company comprehensively implements the design and production of solutions such as production lines and production stations. They specialize in…<i class="fas fa-plus"></i>The company comprehensively implements the design and production of solutions such as production lines and production stations. They specialize in manual, automated, robotic stations with conveyors. In addition they create manual production stations, partly automated, automated or robotic. Production lines can be offered for the following applications:

– dosage,

– gluing,

– labeling,

– laser marking,

– barcode scanning (barcodes, QR, data matrix),

– pick and place,

– internal transport,

– quality control,

– tightness tests,

– applying glue or grease,

– palletizing, depalletizing,

– packaging.

The company has the know-how to develop and create a modern and ergonomic production line that will optimize production time and a high rate of return on investment.Quick View -

Kuka KR150 Serie 2000

<i class="fas fa-plus"></i>The Kuka KR 150 is ideal due to its long robot-reach.

It is a flexible model, due to its capacity to be used for a large range of applications such as welding, cutting, machine tending and others.Quick View -

Kuka KR150-3

<i class="fas fa-plus"></i>The Kuka

KR150-3 is ideal, it can be used for a wide range of applications such as machine tending, deburring, arc welding and others.Quick View -

Kuka KR180L130 Serie2000

<i class="fas fa-plus"></i>The Kuka KR 180L130 is ideal due to its long robot-reach.

This model is ideal due to its capacity to be used for a large range of applications such as machine tending, palletizing, welding and others.Quick View -

Mobile Robots

<i class="fas fa-plus"></i>The company implements mobile robots to support the work of the warehouse, transfer of loading to production lines or in the production line. Possibility to manage a fleet of robots.

Quick View -

Production lines + Full Systems

<i class="fas fa-plus"></i>The company designs and produces production lines and production stations for several applications such as pick and place, palletizing,

packaging, gluing etc..

They are specialized in robotic stations with conveyors. In order to make the procedure more efficient, the company created a 3D vision system, to make the task easier. The robot knows its position while scanning.

With the 3D vision system implemented by the company, cameras and sensors are not required anymore.

The system is controlled by a controller. The kit is installed on the robot. The kit is scanning, it becomes the

eyes of the robot, and the information is sent, so that the robot knows and can measure the length and the task

to be done.Quick View -

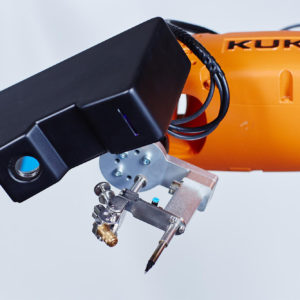

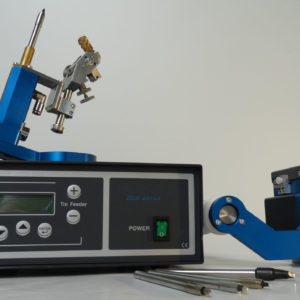

Robotic Soldering Solution

€9.000,00This solder controller is very effective and easy to maintain. It is a stand-alone solution, that can be bought individually.<i class="fas fa-plus"></i>This solder controller is very effective and easy to maintain. It is a stand-alone solution, that can be bought individually.

Quick connection and easy programming makes the product user-friendly. Robotic soldering is also a significant energy saving. Built-in standby menu allows you to lower the temperature so that you do not needlessly heat the soldering tip while waiting. Retooling soldering head is only a tip replacement, so it’s very easy.

The solder controller is great for lead soldering and lead-free soldering. The built-in tip cleaning system is an additional advantage. Additional options include a calibration system and a temperature measurement with a pyrometer. The company ensures high process repeatability and excellent temperature control.Quick View