ABB

-

6-axis robotic arm – ABB IRB2600-12/1.85

€17.630,00• Sharp accuracy • Efficient • Short cycle times • Large working range • Compact design • Increase production capacity An ideal choice for…<i class="fas fa-plus"></i>This robot is a compact and versatile 6-axis industrial robot with a payload capacity of 12 kilograms and a reach of 1.85 meters.

With its advanced control system and high-speed motion capabilities, the IRB 2600 is able to deliver fast, precise, and repeatable results.

Its small footprint and lightweight design make it easy to integrate into existing production lines, and its robust construction ensures reliable operation in demanding environments.

The IRB 2600 is also equipped with a range of safety features, including emergency stop buttons, torque and force sensing, and programmable safety functions, making it a safe choice for use in areas with human-robot collaboration.

A safe choice for your automated production needs.Quick View -

ABB 6640 M2004 / 205

€21.620,00Ideal for the following applications: • Material Handling • Cutting • Milling<i class="fas fa-plus"></i>This serie is especially made for a large range of applications

focusing on high production capacity.

Its high payload and longer reach make it ideal for heavy handling applications.Quick View -

ABB CRB 15000

€29.000,00• Easy to use • Easy programming • Strong and safe robot • Greater productivity Ideal for the following applications: • Material handling • Picking &…<i class="fas fa-plus"></i>Delivery time: 28 weeks

ABB CRB 15000 key features:

• Customer signals 4 signals (for IO, Fieldbus, or Ethernet)

• Functional safety SafeMove Collaborative included all safety functions certified to category 3, PL d

• Axis 1 rotation:

○ Working range: 180° to 180°

○ Axis max speed: 125°/s

• Axis 2 arm:

○ Working range: 180° to 180°

○ Axis max speed: 125°/s

• Axis 3 arm:

○ Working range: 225° to 85°

○ Axis max speed : 140°/s

• Axis 4 wrist:

○ Working range: 180° to 180°

○ Axis max speed : 200°/s

• Axis 5 bend:

○ Working range: 180° to 180°

○ Axis max speed: 200°/s

• Axis 6 turn:

○ Working range: 270° to 270°

○ Axis max speed:200°/s

• Max TCP Velocity : 2.2 m/s

• Max TCP Acceleration: 11.8 m/s2

• Max TCP Acceleration: 36.9 m/s2

• Max TCP Acceleration: 61.6 m/s2

• Acceleration time 0?1 m/s 0.097 s

• Pose repeatability 0.05 mm

• 1 kg picking cycle: 25 x 300 x 25 mm : 0.66 sQuick View -

ABB CRB 15000 with options

€31.000,00• Easy to use • Easy programming • Strong and safe robot • Greater productivity Ideal for the following applications: • Material handling • Picking…<i class="fas fa-plus"></i>Delivery time: 24 weeks

Some key features:

• Customer signals 4 signals (for IO, Fieldbus, or Ethernet)

• Functional safety SafeMove Collaborative included All safety functions certified to Category 3, PL d

• Axis 1 rotation:

○ Working range: 180° to 180° – Axis max speed: 125°/s

• Axis 2 arm:

○ Working range: 180° to 180° Axis max speed: 125°/s

• Axis 3 arm:

○ Working range: 225° to 85° Axis max speed : 140°/s

• Axis 4 wrist:

○ Working range: 180° to 180° Axis max speed : 200°/s

• Axis 5 bend:

○ Working range: 180° to 180° Axis max speed: 200°/s

• Axis 6 turn:

○ Working range: 270° to 270° Axis max speed:200°/s

• Max TCP Velocity : 2.2 m/s

• Max TCP Acceleration: 11.8 m/s2

• Max TCP Acceleration: 36.9 m/s2

• Max TCP Acceleration: 61.6 m/s2

• Acceleration time 0-1 m/s 0.097 s

• Pose repeatability 0.05 mm

• 1 kg picking cycle

25x300x25 mm : 0.66 sQuick View -

ABB IRB 1100

€23.000,00• Offers 35% faster cycle times for increased productivity • Up to 10% space savings • 20% weight reduction for…<i class="fas fa-plus"></i>Delivery time: 38 weeks

• Ideal for the following industries:

Healthcare, Pharmaceuticals, Electronics, Semiconductors and Solar panel manufacturing.

• Electrical compartments are sealed against water and solid contaminants.

Some key features:

The robot is available in 2 versions

• Payload: 4 kg

• IRB 1100-4/0.475 : Robot reach 475 mm

• IRB 1100-4/0.58 0.58

• Mounting: any angle

• Controller OmniCore E10, C30, C90XT

• Integrated signal and power supply: Up to 16 Signals (C1+C2) on wrist

• Integrated air supply: 4 air on wrist (Max. 6 Bar)

• Pose repeatability: RP 0.01 mm

• Axis 1 rotation:

○ Working range: +230° to -230°

○ Axis max speed: 460°/s

• Axis 2 arm:

○ Working range: +113° to -115°

○ Axis max speed: IRB 1100-4/0.475 – 380°/s for IRB 1100- 4/0.58 – 360°/s

• Axis 3 arm:

○ Working range: +55° to -205°

○ Axis max speed : 280°/s

• Axis 4 wrist:

○ Working range: +230° to -230°

○ Axis max speed : 560°/s

• Axis 5 bend:

○ Working range: +120° to -125°

○ Axis max speed: 420°/s

• Axis 6 turn:

○ Working range: +400° to -400°

○ Axis max speed: 750°/sQuick View -

ABB IRB 1100 with options

€29.150,00• Offers 35% faster cycle times for increased productivity • Up to 10% space savings • 20% weight reduction for easy installation • Highest…<i class="fas fa-plus"></i>Delivery time: 38 weeks

• Ideal for the following industries:

Healthcare, Pharmaceuticals, Electronics, Semiconductors and Solar panel manufacturing.

• Electrical compartments are sealed against water and solid contaminants.

Some key features:

The robot is available in 2 versions

• Payload: 4 kg

• IRB 1100-4/0.475 : Robot reach 475 mm

• IRB 1100-4/0.58 0.58

• Mounting: any angle

• Controller OmniCore E10, C30, C90XT

• Integrated signal and power supply: Up to 16 Signals (C1+C2) on wrist

• Integrated air supply: 4 air on wrist (Max. 6 Bar)

• Pose repeatability: RP 0.01 mm

• Axis 1 rotation:

○ Working range: +230° to -230° – Axis max speed: 460°/s

• Axis 2 arm:

○ Working range: +113° to -115°

○ Axis max speed: IRB 1100- 4/0.475 – 380°/s for IRB 1100-4/0.58 – 360°/s

• Axis 3 arm:

○ Working range: +55° to -205°

○ Axis max speed : 280°/s

• Axis 4 wrist:

○ Working range: +230° to -230°

○ Axis max speed : 560°/s

• Axis 5 bend:

○ Working range: +120° to -125°

○ Axis max speed: 420°/s

• Axis 6 turn:

○ Working range: +400° to -400°

○ Axis max speed: 750°/sQuick View -

ABB IRB 1200-5/0.9

€23.800,00• Compact, flexible, fast & functional • Can be mounted at any angle • 15% smaller cells with 10% shorter cycle times. • Functional…<i class="fas fa-plus"></i>Delivery time: 22 weeks

• Available with Food Grade Lubrication, SafeMove, Foundry Plus 2 and Clean Room option

• The robot has Hygienic as an option. Robots with the option Hygienicare equipped with special sealings and coatings, and a special axes 6 stainless steel body and tool flange.

Some key features:

• Axis 1 Rotation motion: +170° to -170°

• Axis 2 Arm motion: +130° to -100°

• Axis 3 Arm motion: +70° to -200°

• Axis 4 Wrist motion: 270° to -270°

• Axis 5 Bend motion: ±130° (not Hygienic robots)

±128° (Hygienic robots)

• Axis 6 Turn motion: Default: +400° to -400° Maximum revolution: ±242°Quick View -

ABB IRB 1200-7/0.7

€23.800,00• Compact, flexible, fast & functional • Can be mounted at any angle • 15% smaller cells with 10% shorter cycle times. • Functional…<i class="fas fa-plus"></i>Delivery time: 22 weeks

• Available with Food Grade Lubrication, SafeMove, Foundry Plus 2 and Clean Room option

• The robot has Hygienic as an option. Robots with the option Hygienicare equipped with special sealings and coatings, and a special axes 6 stainless steel body and tool flange.

Some key features:

• Robot weight: 52 kg

• Axis 1 Rotation motion: +170° to -170°

• Axis 2 Arm motion: +135° to -100°

• Axis 3 Arm motion: +70° to -200°

• Axis 4 Wrist motion: +270° to -270°

• Axis 5 Bend motion: ±130° (not Hygienic robots) ±128° (Hygienic robots)

• Axis 6 Turn motion: Default: +400° to -400° Maximum revolution: ±242iQuick View -

ABB IRB 1300

€30.000,00• High lifting capacity • Available in four main load/reach • Highest payload of any robot in its class. •…<i class="fas fa-plus"></i>Delivery time: 28 weeks

• Available in four main load/reach versions : 12 kg/1.4 m, 11 kg/0.9

m, 10 kg/1.15 m, and 7 kg/1.4 m, the 12 kg variant.

Some key features:

• IRB 1300-11/0.9

Reach: 900mm

Payload: 11kg

Armload: 1 kg

Movement:

○ Axis 1 Rotation: +180° to -180°

○ Axis 2 Arm: +130° to -100°

○ Axis 3 Arm: +65° to -210°

○ Axis 4 Wrist: +230° to -230°

○ Axis 5 Bend: +130° to -130°

○ Axis 6 Turn: +400° to -400°

• IRB 1300-10/1.15

Reach: 1150mm

Payload: 10kg

Armload: 0.5 kg

Movement:

○ Axis 1 Rotation: +180° to -180°

○ Axis 2 Arm: +155° to -95°

○ Axis 3 Arm: +65° to -210°

○ Axis 4 Wrist: +230° to -230°

○ Axis 5 Bend: +130° to -130°

○ Axis 6 Turn: +400° to -400°

• IRB 1300-7/1.4

Reach: 1400mm

Payload: 7kg

Armload: 0.5 kg

Movement:

○ Axis 1 Rotation: +180° to -180°

○ Axis 2 Arm: +155° to -95°

○ Axis 3 Arm: +69° to -210°

○ Axis 4 Wrist: +230° to -230°

○ Axis 5 Bend: +130° to -130°

○ Axis 6 Turn: +400° to -400°

• IRB 1300-12/1.4

Reach: 1400mm

Payload: 12kg

Armload: 0.5kg

Movement:

○ Axis 1 Rotation: +180° to -180°

○ Axis 2 Arm: +155° to -95°

○ Axis 3 Arm: +69° to -210°

○ Axis 4 Wrist: +230° to -230°

○ Axis 5 Bend: +130° to -130°

○ Axis 6 Turn: +400° to -400°Quick View -

-

ABB IRB 140 S4C+ M2000

<i class="fas fa-plus"></i>Because of its load and reach capacities, the robot ABB IRB 140 is known for its rapidity, and flexibility improving considerably the yield of production

Quick View -

ABB IRB 1400

<i class="fas fa-plus"></i>The IRB 1400 offers fast and reliable work cycles that boost productivity. The robot is well-proven in arc welding, material handling and process applications. The ability to adjust process speed and position is the key to achieving optimum manufacturingnaccuracy with little or no rejects.

Quick View -

ABB IRB 1400 Multi Move IRC5 Welding System

<i class="fas fa-plus"></i>Multi move system with 3 robots and a single control. The ABB IRB 1400 robot model is designed for arc welding. It is the welding model par excellence. This ABB IRB 1400 uses the IRC5 robot controller, which is equipped with a path control system, user-friendly programming unit, flexible RAPID language and extensive communication possibilities. Multi move version, consisting of – 3 ABB IRB 1400 robots – 1 IRC5 control – 1 teach pendant

Quick View -

ABB IRB 1400 S4CPLUS M2000

<i class="fas fa-plus"></i>ABB IRB 1400 robot is fast, reliable, and affordable, making it the perfect choice for companies looking to automatize their production lines. IRB 1400 S4C M98 and S4C+ M2000 controllers, are ideal for a limited work place when a large work-processing area is required. The IRB 1400 will increase productivity with its fast and reliable work cycles, long maintenance intervals and low noise levels. Less maintenance means more profits resulting from less down time. IRB 1400 S4C M98A and S4C+ M2000, is a favourite for any company in need of an arc welder, material handling, and process applications. With a handling capacity of 5kg and a supplementary load on the upper arm that can handle 18kg, combined with speed and accuracy allowing for high performance operations.?

Quick View -

ABB IRB 1400 with Fronius

The ABB IRB 1400 with Fronius Trans synergic 4000 + cleanser TC1000 is a top-of-the-line robotic welding system that promises…<i class="fas fa-plus"></i>The ABB IRB 1400 with Fronius Trans synergic 4000 + cleanser TC1000 is a highly efficient robotic welding system that comes equipped with everything you need for successful welding. This system includes the robot, control, cable, instruction manual, and wiring diagram, allowing for easy installation and operation. Additionally, the disk driver feature allows for seamless data saving, ensuring that your welding projects stay organized and easily accessible. The system also boasts a pulse welding feature that enables precise and accurate welding, regardless of the material. Whether you’re a seasoned welder or a novice, the ABB IRB 1400 with Fronius Trans synergic 4000 + cleanser TC1000 is a reliable and effective choice.

Quick View -

-

ABB IRB 1600

<i class="fas fa-plus"></i>Additional applications in which this ABB IRB robot can perform include pick and place, laser welding, and plasma welding

Quick View -

ABB IRB 1600-8/1.45 IRC5 foundry plus – complete

<i class="fas fa-plus"></i>The IRB 1600 is a fast and strong bending backwards robot. The robot is not only a flexible allrounder also a specialist with competitive edge in each application.

Quick View -

ABB IRB 1600iD IRC5 M2004 Multi move

<i class="fas fa-plus"></i>ABB IRB 1600ID (Integrated Dressing) robot model is designed for arc welding. The wiring situation and the process hoses are located inside the upper arm. Therefore, failures due to wiring breakage are avoided. Cables and hoses last longer with this protection configuration. ABB IRB 1600iD, consists of 6 axes and can be installed in any position: floor, ceiling or at an angle.This ABB IRB 1600ID uses the IRC5 robot controller, which is equipped with a trajectory control system, friendly programming unit, flexible RAPID language and extensive communication possibilities. Also available in multi move version, consisting of – 2 ABB IRB 1600iD robots – 1 IRC5 control – 1 teach pendant

Quick View -

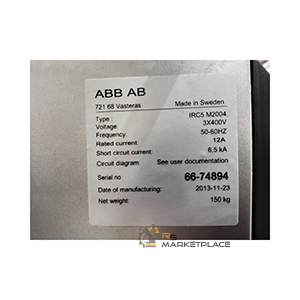

ABB IRB 2400

• One of the most popular model • Several mounting options available • Flexible Ideal for the following applications: Arc welding, Cutting, Deburring,…<i class="fas fa-plus"></i>Some key features:

• Controller IRC5 M2004

• Serial number: 6674894

• Date manufacture: 2013Quick View -

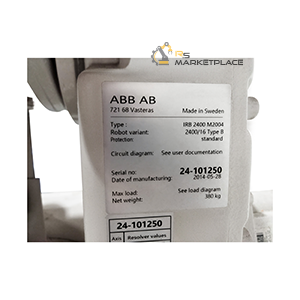

ABB IRB 2400 16

• One of the most popular model • Flexible • Several mounting options available Ideal for the following applications: Arc…<i class="fas fa-plus"></i>Some key features:

• Type: IRB2400 M2004

• Robot weight: 380 kgQuick View -

ABB IRB 2400 L

<i class="fas fa-plus"></i>IRB 2400 is a dedicated high performance robot for process applications where the required accuracies are very demanding.

The robust construction and use of minimum parts contribute to high reliability and long intervals between maintenance.

Quick View