Universal Robots

-

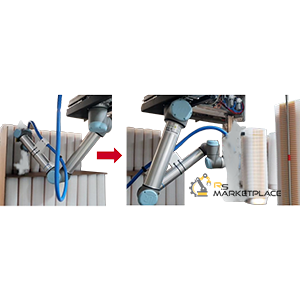

Cobot based denester

Plastic and paper containers have become a staple in various industries due to their capacity to store and safeguard products…<i class="fas fa-plus"></i>Our products are packaged with care to ensure maximum protection during transportation and storage. For products on a pallet, we use rigid plastic tubs that are perfect for suction cup picking and lip support, with each stack weighing up to 3 kg and stacking up to 700 mm. For products in a cardboard box, our cups and pints are also rigid enough for suction cup picking, yet stable enough to be picked up by the bottom cup. Each stack can hold up to 2 kg and stack up to 700 mm. No matter the packaging, we ensure that our products arrive at their destination safely and securely. Our pallets come in two sizes, UK 1000 x 1200 [mm] and EUR 800 x 1200 [mm], to accommodate different storage and transportation needs.

Quick View -

Cobot solution for carton loading

Carton loaders are a convenient solution that can save time and labor costs in a production line. The machine removes…<i class="fas fa-plus"></i>Cobot solution for carton loading key features:

- Compact

- Continuous operations

- No fence system needed

- Mobile, easy to move

- Easy to install and configure – less than a day

- Low noise level

Cobot solution for carton loading specification:

• Average cycle time: 40 s per bundle, 20 s per

interlayer

• Configurations: Left or right hand-side

• Changeover of SKUs or line: Auto recipe

download, location agility

• Pallet height: max. 1.4 m / 1.7 m using a 500

or 800mm actuator

• Customized gripper with vision system and trimming module

• Power supply: 110 VAC / 230 VAC

• Max. 1200 VA

• Pallet space for Euro (800 x 1200 mm),

US (1067 x 1067 mm), UK (1200 x 1000 mm)

• Emergency stopThe company is renowned for its immense experience in integrating cobot solutions into production lines, having deployed over 700 unique robotic applications in various industries. Not only do they emphasize the importance of operator safety, they also ensure that their cobotic cells adhere to ISO TS 15066 standards. This includes a rigorous screening process including third-party testing, ensuring all drafts of the system are safe and secure before implementation. As an example of this commitment to safety, their automated carton loading solution features numerous safeguards to protect operators and maximize productivity.

Quick View -

Flexible industrial robot – Universal UR5

€15.732,00• Lightweight • Adaptable collaborative industrial robot • Ideal for a wide range of applications • Easy programming • Fast…<i class="fas fa-plus"></i>The Universal UR5 is a 6-axis robotic arm with a reach of 850mm and a maximum payload of 5kg.

The robot features a high-performance controller and advanced software that allow for easy programming and flexible operation.

The UR5’s compact design makes it ideal for integration into production lines, and its lightweight construction enables quick and easy installation.The Universal UR5 is a versatile and flexible industrial robot arm that is ideal for a wide range of applications.

With its 5-axis design and lightweight construction, the UR5 provides fast, accurate, and reliable performance

in even the most demanding environments.

Whether you need to automate manual tasks, increase production efficiency,

or improve product quality, the Universal UR5 is the perfect solution.Quick View -

Folding boxes solution

€55.000,00Benefits: Our solution does the following steps: • Pick up boxes • Open the boxes • Lift them • Tape them to close…<i class="fas fa-plus"></i>The Folding boxes solution is a must-have for small and medium-sized businesses in the food, agriculture, pharmaceutical, and health industries. This system has been specifically designed to handle various box dimensions and prepare them for product filling on the belt.

With the Folding boxes solution, you can say goodbye to the hassle of manually folding boxes which can be time-consuming and exhausting.

The efficiency that comes with this system will go a long way in boosting productivity and ultimately, customer satisfaction. Get the Folding boxes solution today and let it take care of your packaging needs!

Quick View -

Full system for painting application

€85.000,00Benefits: • Quick to install • Ready to service • Easy to maintain • Remote assistance • Cost effective solution *Starting price<i class="fas fa-plus"></i>Our vendor is customizing the painting services according to the customer needs.

Benefits:

• Fast and optimized spray production processes via path recording• Quick to install

• Easy to maintain

Ideal for the following users:

• For small and medium-sized artisan

• Manufacturing companies

• Metal working companies

• Wood industryQuick View -

Palletizing Robotic Cell

The benefits of the palletizing robotic cell: • Operational in less than 10 minutes. • Versatile • Higher speed and…<i class="fas fa-plus"></i>Palletizing Robotic Cell Key features:

• Dimensions: 1000 x 1300mm

• Weight: 250kg

• Reach: 1300mm

• Load capacity: 10kg

Pallet type:

EU 1, EU 2, EU 6, US 1, US 2, AU 1, ASIA 1

• Box dimension: min 200 x 200mm

• Cycle time: Up to 10 cycles/min

• Max height: 2.25 m

• Inputs and outputs:

2 digital inputs

2 digital outputs

3 security digital inputs

• Ethernet (RJ45)

• Input voltage: 230VAC

• Transportable: With pallet trucks or forklift

• Air: inlet 6 Bar, diameter 10

Palletizing Robotic Cell Standard equipment:

• UR 10 robot

• Telescopic column 900 mm

• Vacuum system

• Palletizing SoftwareQuick View -

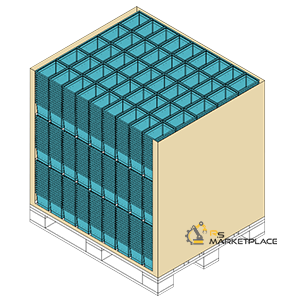

Palletizing solution with UR cobot

€85.000,00Benefits: • Quick to install • Ready to service • Easy to maintain • Cost effective solution Ideal for the following users: • For…<i class="fas fa-plus"></i>Palletizing solution with UR cobot key features:

- No need for physical barriers

- Suitable for any type of roller conveyor or conveyor belt

- The system stores the palletizing mosaic from the operator or from a MES / ERP system.

- Can be used on several lines.

- Very short retooling times and recipe / mosaic change.

- Versatile: Able to work with vacuum or electric grippers alike.

- Guided reprogramming via graphic interface or direct questions to the operator.

- Working area on two 1200x800mm euro pallets (option 1200 ? 1000) with the possibility of picking up and depositing full / empty pallets without stopping the system

- Maximum loading weight of 11.5kg

- From 5 to 8 pick and Place per minute depending on the type of installation, the load to be handled and the height of the pile

- Minimum box dimensions: 150x150x150 mm

- Sensor is integrated in the gripping tool

- About 68 dB (A) in production

- Power supply 220V 50hz

- Power consumption less than 1000W

- 6 bar compressed air inlet with internal regulation and filtration system

Quick View -

UNIVERSAL – UR6-85-5-A

The UR6 is a lightweight, adaptable collaborative industrial robot that tackles medium-duty applications with ultimate flexibility. The robot is designed…<i class="fas fa-plus"></i>The UR6 is a lightweight, adaptable collaborative industrial robot that tackles medium-duty applications with ultimate flexibility. The robot is designed for seamless integration into a wide range of applications.

Quick View -

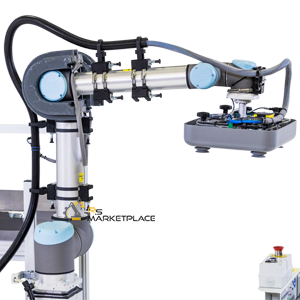

Universal Robot Fronius welding

The Universal Robot welding solution is the ultimate solution for those who need high-quality welding service. With the latest model…<i class="fas fa-plus"></i>The Universal Robot welding solution has introduced the newest robot model that boasts higher accuracy and better mechanics than the CB-Series. One of its significant software advantages is that it can start at any point in the robot program and has much higher path accuracy than the CB-series. If you opt for the additional bumper, your remote control will have a protective cover (Original ARMOR).

With the operateONE quick-start buttons, including START/STOP/RESET/Emergency stop/POTI, and the ergonomic frame for UR Teachpanel, along with the key switch for the laser light barriers, you can get started immediately. The Siegmund welding Table Professional 750 is also included, with its size of 1500x1000x200mm, plasma-nitriert, and 28mm holes. This set is complete with Fronius welding equipment that is ready for welding. The Fronius TPS 400i Pulse Schweisanlage with WP Pulse, Syn, PMC, NFC, wifi with Robot-welding hose + Modbus Interface, prepared for 1.0mm steel wire, is the cherry on top. This solution has it all for your welding needs.

Quick View -

Universal Robots UR5

€14.800,00<i class="fas fa-plus"></i>The UR5e is a lightweight, adaptable collaborative industrial robot that tackles medium-duty applications with ultimate flexibility. The UR5e is designed for seamless integration into a wide range of applications.

Quick View -

Universal UR5 – 2016

€15.732,00• Lightweight • Adaptable collaborative industrial robot • Ideal for a wide range of applications • Easy programming • Fast… -

UR10 – 2021

€27.000,00Like New • The UR10 is a collaborative robot with 6 axes of movement • It has a payload capacity…<i class="fas fa-plus"></i>As a manufacturing or production company, you are always on the lookout for ways to improve your processes and increase efficiency. One solution that is gaining popularity in the industry is collaborative robots, or cobots.

And if you’re in the market for a cobot that is reliable, precise, and easy to use, the Universal Robots UR10 should be at the top of your list.The UR10 is a collaborative robot with a payload capacity of up to 10kg and a reach of 1300mm.

This makes it ideal for a wide range of tasks such as packaging, palletizing, assembly, and pick and place.

Its six axes and articulated structure allows for maximum flexibility and precision, with a repeatability of ±0.1mm.

The UR10 is also incredibly easy to set up and program, thanks to its patented technology and intuitive 3D visualization.

Even untrained operators can unpack the robot, mount it, and program its first task in less than one hour.One of the standout features of the UR10 is its ease of use. It can be programmed through manual movements of its arm, making it accessible to anyone regardless of robotic programming experience.

Fine-tuning the application movements can also be done using its user-friendly touchscreen tablet.

The UR10 is also incredibly versatile, with mounting options that include floor, ceiling, and wall, allowing it to accommodate most production lines.But what really sets the UR10 apart from other cobots on the market is its enhanced safety features.

Over 80% of Universal’s UR10 cobots are able to operate alongside workers without the use of safety barriers, thanks to its force sensors that prevent collisions with workers from occurring.

This means that the UR10 can directly assist workers, significantly increasing productivity rates. Additionally, the UR10’s lightweight design (it weighs in at just 28.9kg) makes it easy to move and reposition as needed.Investing in the UR10 from Universal Robots can help you save time and increase productivity on your production line.

Its larger reach and payload capacity make it an effective choice for tasks that require precision and reliability across a larger area.

And with its ease of use and quick setup time, you can start reaping the benefits of the UR10 in no time. So don’t settle for less when it comes to your production line.

Choose the UR10 from Universal Robots for a collaborative robot that delivers precision, reliability, and ease of use.Quick View