SP005-0113-AA

-

a cutting-edge solution 3D printed grippers

✓ Gripper specially developed using the 3D printing process<i class="fas fa-plus"></i>These grippers are specially developed using the 3D printing process.

They have internal vacuum generation capabilities and can be customized to suit specific needs.Customizable design: The grippers can be 3D printed to fit a wide range of objects

and are customizable to meet the specific requirements of your application.Lightweight: The grippers are 3D printed using high-strength, lightweight materials,

making them easy to manipulate and reducing the load on the robotic arm.Durable: The grippers are designed to withstand the rigors of industrial environments

and provide long-lasting performance.Cost-effective: 3D printing technology allows for faster production and lower costs

compared to traditional manufacturing methods.With their advanced design and 3D printing technology, the grippers offer a cost-effective

and customizable solution for robotic grasping and manipulation.Quick View -

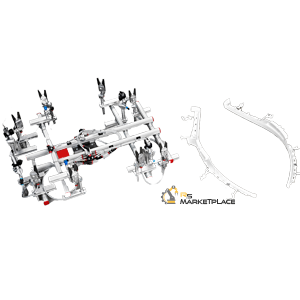

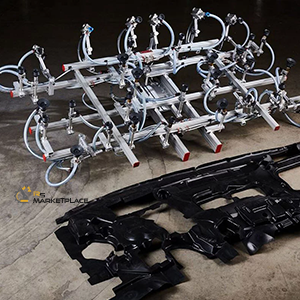

A revolutionary solution – Multiple-removal gripper

✓ Adaptation of existing gripping systems ✓ Safe component removal ✓ Precise removal process<i class="fas fa-plus"></i>Multiple-removal gripper is a revolutionary solution for efficient and precise part removal in industrial automation applications.

This gripper is designed to be lightweight, durable and customizable,

making it ideal for a wide range of applications.This gripper is designed to remove 32 razor blade covers at once.

It uses tubular gripper profiles and has the advantage of several suction pads that can

be connected to one vacuum source.Multiple-part removal: The gripper is designed to remove multiple parts at once,

making it ideal for high-volume production lines.Customizable design: The AGS Multiple-removal gripper can be customized to fit a wide range of objects

and is built to meet the specific requirements of your application.Lightweight: The gripper is 3D printed using high-strength, lightweight materials,

making it easy to manipulate and reducing the load on the robotic arm.Durable: The gripper is designed to withstand the rigors of industrial environments

and provide long-lasting performance.Quick View -

Camera – sensor holder – system

€195,00Sensors and camera system can be attached in any chosen application.<i class="fas fa-plus"></i>Sensors and camera system can be attached in your application. The Kit suits multiples systems, e.g.

– Camera mounted with standard components

– Camera bracket with adjustment X-Y

– Combi bracket – camera and lightQuick View -

Complete Gripper / EOAT

€500,00Choose from a variety of grippers: • Insert Gripper (for bolts, nuts) • Removal Gripper • Fabric Gripper • In-mold…<i class="fas fa-plus"></i>The company is ready to build the complete gripper, either using the components out of our two systems (PreciGrip or channel nut) or by doing the construction additive, with laser welding technology. Two kinds of documentation are available. A simplified version or the DIN documentation, containing electric / pneumatic diagrams and the declaration of conformity.

Quick View -

Customized Gripper

We customize your gripper. Just tell us more about you and your product: • Type of Product Handled • Industry…<i class="fas fa-plus"></i>Get the right gripper for your application.

Experts with many years of experience mainly but not solely in the plastics industry know exactly what you need.

Get in touch and share more information about the type of product you need to handle.Quick View -

EOAT / Gripper Starter Set

€800,00The Set contains: • Conversion Set system Ideal for customers that use suction cups, gripper arms, etc. from alternative brands.…<i class="fas fa-plus"></i>The Gripper Conversion Set system is for customers that use suction cups, gripper arms, etc. from alternative brands.

The Gripper Starter Set is ideal for customers that want to delegate the challenging building of End Arm Tooling to experts.Quick View -

Extraction gripper

✓ Adaptation of existing gripping systems ✓ Safe component removal ✓ Suitable for all robot systems<i class="fas fa-plus"></i>Our removal gripper safely removes plastic parts or workpieces from injection molding machines.

The parts are usually deposited on a conveyor belt or in a container.Quick View -

Grip the sprue – Sprue trimming

✓ Adaptation of existing gripping systems ✓ Safe component removal ✓ Suitable for all robot systems<i class="fas fa-plus"></i>This gripper removes the part and then folds the cutting knives

into position and cuts off the sprues.A sprue trimming gripper is a robotic end-effector that is designed to grip

the sprue and trim it away from the finished part.These grippers typically use a cutting mechanism, such as a blade or a wire,

to trim the sprue. Some of them could use a pneumatic or electric actuator to move the blade or wire.Sprue trimming grippers are used to automate the sprue trimming process,

which can be a time-consuming and labor-intensive task.

They allow for faster and more consistent sprue trimming, which can increase production

efficiency and reduce the risk of errors. They are also used in a wide range of industries,

including automotive, consumer goods, and medical device manufacturing.Quick View -

Gripper construction kit

✓ Adaptation of existing gripping systems ✓ Safe component removal ✓ Suitable for all robot systems<i class="fas fa-plus"></i>Our standard gripper construction kit, which is based on the well-known Channel Nut clamping profile 25/25 and includes

components that are compatible with systems using clamping diameters of 10, 14, 20, and 30mm.

We offer over 2500 different components that have been developed based on practical experience and our own gripper construction expertise.Quick View