KUKA

-

Fast and precise – KUKA KR30 HA

€19.500,00Ideal for the following applications: Milling, Drilling, Welding, Pick & Place Refurbished and Painted<i class="fas fa-plus"></i>The KUKA KR30 HA is a high-performance industrial robot designed for flexible

and efficient automation solutions. With its 30 kg payload capacity and compact design,

it is perfect for a variety of applications, including assembly, handling, and packaging.

The robot is equipped with advanced technology such as fast and precise motion control,

intuitive programming, and easy maintenance, making it a valuable asset for businesses of all sizes.

Whether you’re looking to improve productivity, increase accuracy, or streamline your production processes,

the KUKA KR30 HA is the ideal solution.Quick View -

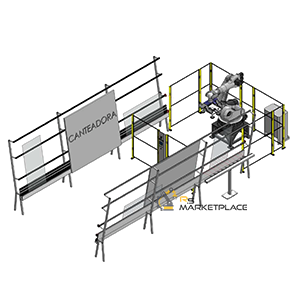

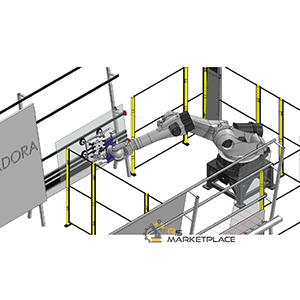

Handling solution for glass sheets

A new handling solution for glass sheets has been designed with a robotic cell. This robotic cell is equipped with…<i class="fas fa-plus"></i>Handling solution for glass sheets main elements:

● Kuka KR210

The KUKA KR210 6-axis industrial anthropomorphic robot we are utilizing is specially equipped with a high-powered KRC2 controller, ensuring optimal performance. With this system, we can handle products with incredible speed and accuracy. All the necessary sensors and physical stops provide the robot with exact product location coordinates. This allows to automate these processes quickly and precisely in line with the quickening pace of industry workflow demands.

● Clamp tool

The innovative clamp tool is designed and configured to capture and deliver the glass sheets with ease. This machine works by using a system of compression blades that removes the bags from a capture table. These features provide better control over the process ensuring accuracy and reliability for every job that requires material handling. Furthermore, the tools are safe and user-friendly, so any operator can understand how to use them quickly and efficiently. The clamp tool certainly makes the process of moving heavy bags much faster and easier than other manual methods used in logistics and transportation.

● Modular belt conveyor

A handling solution for glass sheets provides the ultimate precision in product handling. Equipped with the necessary stops and defenses to enable optimal gripping, as well as sensors and physical stops to provide the robot with information on positioning of the product, this machinery offers an efficient automated means to move materials quickly and accurately. With its low risk factor and increased safety by computer and technology integration when it comes to manipulating objects, this type of machinery is sure to play a growing role in industrial steps around the globe.Quick View -

High-performance industrial robot – KUKA KR60 HA

€19.500,00Ideal for the following applications: Milling, Drilling, Welding, Pick & Place Refurbished and Painted<i class="fas fa-plus"></i>The KUKA KR60 HA is a high-performance industrial robot designed for demanding applications.

With its advanced control technology and high payload capacity,

the KR60 HA provides fast, accurate, and reliable performance, making it the perfect solution for a wide range of automation needs.

Whether you need to automate manual tasks, increase production efficiency, or improve product quality, the KUKA KR60 HA is the ideal choice.The KUKA KR60 HA is a 6-axis robotic arm a maximum payload capacity of 6kg.

The robot features a compact and lightweight design, making it ideal for integration into tight spaces and production lines.The KR60 HA features advanced motion control algorithms, which ensure smooth and accurate motion,

even in complex applications. The robot’s high-performance controller provides fast and reliable operation,

and its safety features, including speed monitoring, torque control, and protective stop functions, ensure safe and efficient operation.Quick View -

Kuka KR 10 R1100 sixx New

• Fast and precise robot • Robust & Reliable • Several mounting options available Ideal for the following applications: Assembly, Material Handling, Loading. -

Kuka KR 10 R1100 sixx Used

• Fast and precise robot • Powerful and reliable • A safe choice for use in areas with human-robot collaboration Ideal…<i class="fas fa-plus"></i>The Kuka KR 10 is a high-performance 6-axis industrial robot designed for a wide range of applications,

including welding, material handling, and assembly.

With a payload capacity of 10 kilograms and a reach of 2.6 meters, it is well-suited for a variety of tasks in a range of industries.

The KR 10 features advanced motion control technology and fast, precise movement capabilities,

making it an ideal choice for high-speed production environments.

Its durable construction and wide range of available options and accessories make it a versatile

and reliable choice for many different applications.Quick View -

-

-

KUKA KR 180 KRC2 complete / Stud Welding Robot

<i class="fas fa-plus"></i>Thanks to their modular design, the robots

can also be quickly retrofitted for increased payload or reach.

Their advantages are flexible production and rapid commissioning.Quick View -

KUKA KR 180 Serie 2000 with traversing axes 3m

<i class="fas fa-plus"></i>Thanks to it powerful motors,

gear units and servo drives ? Series 2000 robots achieve greater performance. Due to their modular design and the wide range of expansion options, these robots

can be quickly upgraded or converted, and therefore be quickly adapted to the production.Quick View -

KUKA KR 200L170-2 Comp

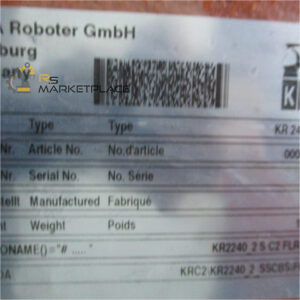

<i class="fas fa-plus"></i>The KUKA Comp heavy-duty robots comprise the following models: KUKA KR200-2 Comp, KR200L170-2 Comp and KR200L140-2 Comp. These robots are 6-axis and lighter and faster. They are equipped with a more powerful KRC2 ED05 controller. The KRC2 controller, 2005 edition (ED05), guarantees high reliability and continuous access to the benefits of KUKA’s state-of-the-art technology. Up to two external axes can be integrated into the basic controller and up to six external axes into a higher-level controller. The controller is characterized by its easy maintenance, good accessibility, and modular structure, which allows components to be exchanged quickly and easily.

Quick View -

KUKA KR 210 K

<i class="fas fa-plus"></i>This industrial robot?is a top performer in its class due to its high flexibility and long reach with optimal payload capacity.

Quick View -

KUKA KR 210 KRC2 Edition 5

<i class="fas fa-plus"></i>The KR 210 KRC2 Ed05 comprises a spherical work space, making it ideal for installations where space saving is sought. Equipped with KRC2 Ed05 controller running under Windows XP. The KRC2 Ed05 controller facilitates programming through the Microsoft Windows user interface. It is expandable, it can be integrated into networks via a bus. The KRC2 Ed05 controller is characterized by having open PC technology and network-compatible. It has free slots for installing additional axes, Device Net and Ethernet for common bus systems. It includes floppy drives and CD-ROMs for data backup Ease of operation and programming via the KUKA Control-Panel (KCP) with Windows user interface programming console.

Quick View -

KUKA KR 210, KRC2 with linear axes 8,5 m

<i class="fas fa-plus"></i>The KUKA KR 210 with KRC2 and linear axes 8.5 m is a powerful industrial robot designed

for demanding automation tasks. With its 210 kg payload capacity and 8.5-meter reach,

it is ideal for a wide range of applications, including material handling, packaging, and machine loading.

This robot is equipped with advanced technology, including fast and precise motion control,

intuitive programming, and easy maintenance, making it a valuable asset for businesses of all sizes.Quick View -

KUKA KR 210K, Serie 2000, KRC2 / console robot

<i class="fas fa-plus"></i>Thanks to their modular design and the wide range of expansion options, these robots

can be quickly upgraded or converted.

This category offers a wide variety of models, as well as

numerous expansion options; this way, the robots

can also be quickly retrofitted for increased payload or reach.

The advantages are flexible production and rapid commissioning.Quick View -

KUKA KR 210L150-2 2000

<i class="fas fa-plus"></i>The KR 210L150-2 2000 KRC2 Ed05 comprises a spherical work space, making it ideal for installations where space saving is sought. Equipped with KRC2 Ed05 controller running under Windows XP. The KRC2 Ed05 controller facilitates programming through the Microsoft Windows user interface. It is expandable, it can be integrated into networks via a bus. The KRC2 Ed05 controller is characterized by having open PC technology and network-compatible. It has free slots for installing additional axes, Device Net and Ethernet for common bus systems. It includes floppy drives and CD-ROMs for data backup Ease of operation and programming via the KUKA Control-Panel (KCP) with Windows user interface programming console.

Quick View -

KUKA KR 210L180-2 2000

<i class="fas fa-plus"></i>The KR 210L180-2 2000 KRC2 Ed05 comprises a spherical work space, making it ideal for installations where space saving is sought. Equipped with KRC2 Ed05 controller running under Windows XP. The KRC2 Ed05 controller facilitates programming through the Microsoft Windows user interface. It is expandable, it can be integrated into networks via a bus. The KRC2 Ed05 controller is characterized by having open PC technology and network-compatible. It has free slots for installing additional axes, Device Net and Ethernet for common bus systems. It includes floppy drives and CD-ROMs for data backup Ease of operation and programming via the KUKA Control-Panel (KCP) with Windows user interface programming console.

Quick View -

KUKA KR 240-2KRC2ed 05

<i class="fas fa-plus"></i>The KR 240-2 is part of KUKAs Series 2000 robots. Due to it?s modular design and a wide range of expansion options, this all-rounder can be quickly upgraded or converted to suit your application.

Quick View -

KUKA KR 3 KRC3

<i class="fas fa-plus"></i>The KR 3 is ideal when small components and products have to be manufactured in a reduced space. It can be used wherever short production cycles are required with the highest level of output. The robot especially appealing to the electronics industry.

Quick View -

KUKA KR 30-3 Profibus

The KUKA 30-3 is a light-payload industrial robot mainly used for arc welding and material removal applications.<i class="fas fa-plus"></i>The KUKA 30-3 is a light-payload industrial robot mainly used for arc welding and material removal applications.

Quick View -

KUKA KR 360 450-2pA

<i class="fas fa-plus"></i>The KR 360 450-2 PA is an extremely powerful and reliable palletizing robot. Thanks to the special palletizing mode, this robot can lift particularly heavy payloads.

Quick View -

Kuka KR 5

The Kuka KR 5 for arc welding is a powerful and precise robot that offers top-notch performance for industrial arc…<i class="fas fa-plus"></i>The Kuka KR 5 is a robotic arm that has gained popularity in industries that require automation. With its precise movements and ability to repeat tasks with high accuracy, the KR 5 has become a sought-after option for companies looking to streamline their manufacturing processes. Its compact design allows it to fit into tight spaces and its modular system makes it customizable for various applications. The KR 5 is also easy to program, making it a user-friendly option for both experienced operators and those new to robotics. Overall, the Kuka KR 5 offers a versatile solution for businesses seeking to increase efficiency and productivity.

Quick View -

Kuka KR 60

The Kuka KR 60 is a perfect example of the modern industrial robot, taking center stage in today's highly automated…<i class="fas fa-plus"></i>The Kuka KR 60 is a versatile robot for a variety of tasks, from laser welding to machining. With a weight of 665 kg, it’s a sturdy and reliable machine to handle demanding workloads. The robot comes equipped with 2 pieces of control, a control cabinet, and a range of other features that make it a top choice for those looking for precision and efficiency in their manufacturing processes. The software version is KSS 8.3, which makes it easy to integrate the robot into existing systems, while the touch panel Kuka KCP4 allows for precise and intuitive control. With a connecting cable that reaches 7 meters and a repeatability of 0.05mm, the Kuka KR 60 is a top-of-the-line machine that stands ready to tackle even the toughest jobs.

Quick View -

Kuka KR125-3

The Kuka KR125-3 is a robotic arm ideal for various applications such as machine tending, deburring and arc welding. This…<i class="fas fa-plus"></i>The Kuka KR125-3 robot is a great solution for your heavy payload application needs. It builds upon the features of its predecessor, the Kuka KR125/2, and runs faster and more accurately. It has an arm reach of 2400 mm, it can bear weights ranging from 125 kg to 200 kg with excellent repeatability of 0.2 mm. A great addition is its ability to network with other systems via standard bus protocols. For situations requiring additional axes, two slots are provided in the cabinet and a smooth connection allowing integration of six additional axes through an additional cabinet is also available – making this a highly versatile system for handling, machining, loading, and unloading operations.

Quick View -

-

-

-

-

KUKA KR150 L130 2000

€12.250,00Ideal for the following applications: • Milling • Drilling • Palletizing Refurbished and Painted<i class="fas fa-plus"></i>This robot had electronic and mechanical maintenance and painted.

It looks like new and it worked less than 26000 hours.

This robot is pretty suitable for milling, drilling and palletizing operations.

Can be used in the following industries:

• Wood

• Metal

• Steel

• Electronics

• AutomotiveQuick View -

-

Kuka KR150 Serie 2000

<i class="fas fa-plus"></i>The Kuka KR 150 is ideal due to its long robot-reach.

It is a flexible model, due to its capacity to be used for a large range of applications such as welding, cutting, machine tending and others.Quick View